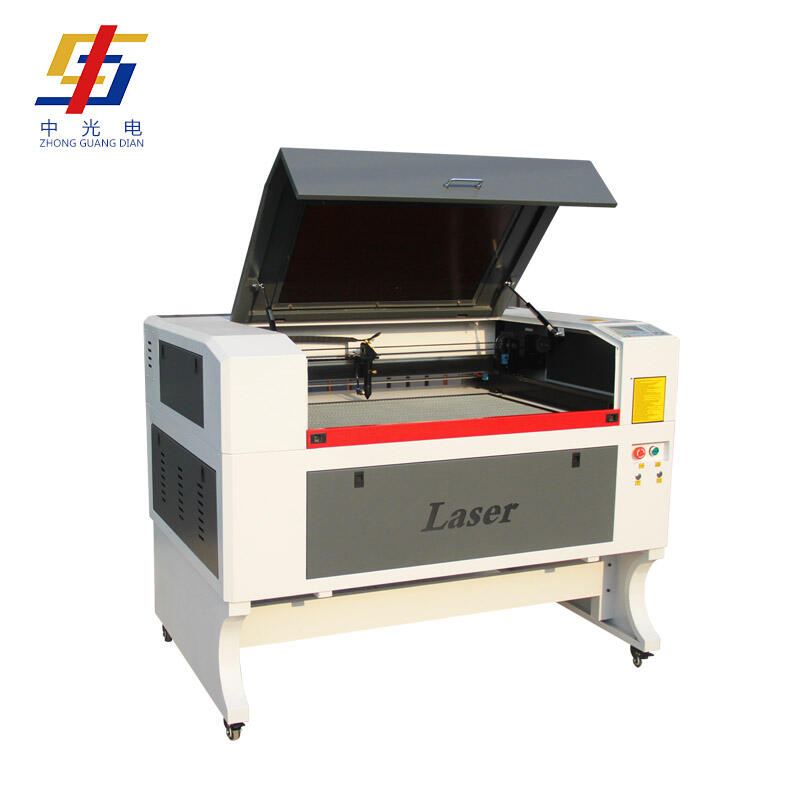

Laser Engraving Machine Focusing Lens

◆ China PVD ZnSe material, excellent optical properties, up to 80W CO2 laser resistance.

- Overview

- Related Products

Product Introduction

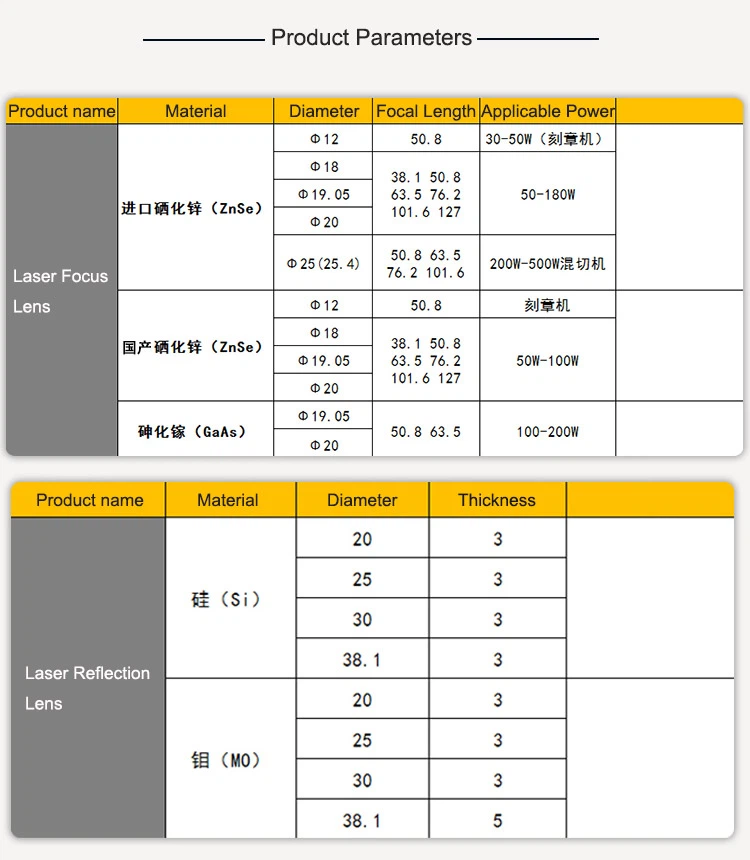

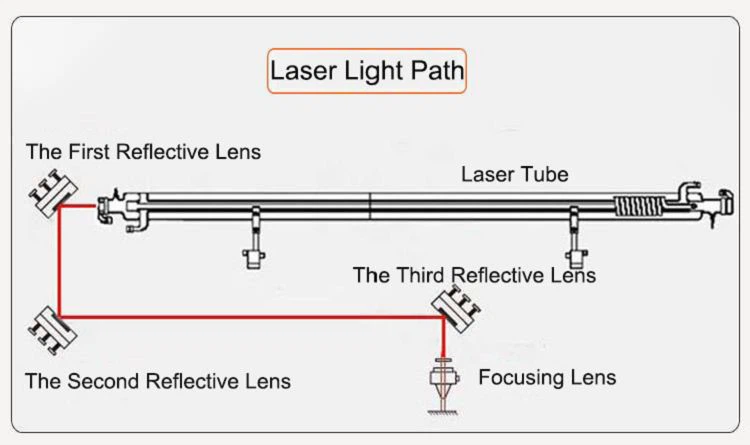

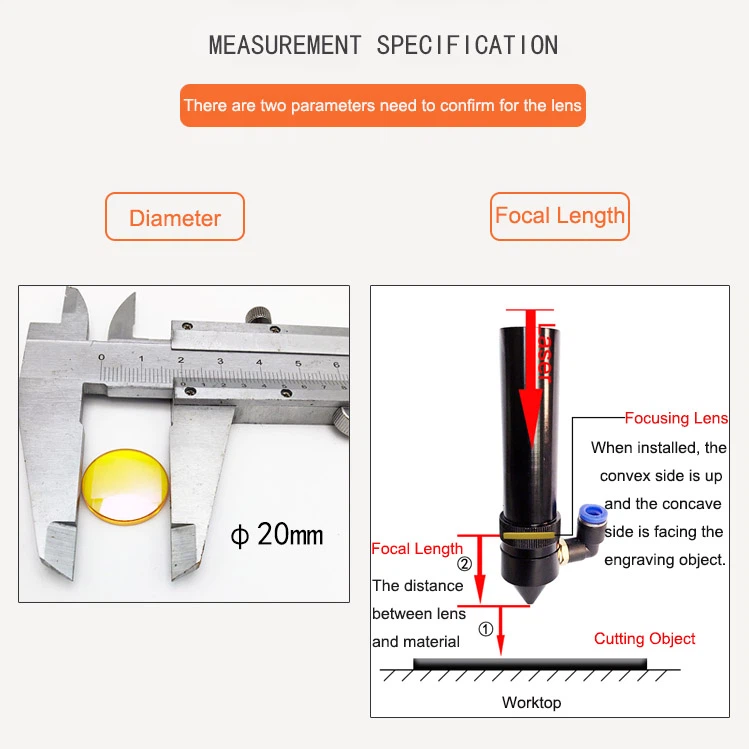

Laser engraving machine focusing lenses are precision optical components designed to focus laser beams for engraving and cutting applications. Made from high-quality materials like PVD ZnSe, these lenses boast a transmittance rate exceeding 99.9%, ensuring maximum efficiency during operation. With diameters often around 20 mm and focal lengths ranging from 25.4 mm to 190.5 mm, they are engineered to handle various power ranges, typically from 30W to 100W for CO2 lasers.

Product Features

● High-Quality Material: The focusing lens is made of high-quality PVD ZnSe crystal material, which has excellent optical performance and a transmittance of up to 99.9%, ensuring the effective transmission of the laser beam. In addition, the PVD ZnSe material has excellent high temperature resistance and can withstand up to 90W CO2 laser power and adapt to high temperatures and harsh environments, thus ensuring the stability and reliability of the lens in long-term use.

● Lasting Durability: The laser engraving machine focusing lenses are made of high-quality PVD ZnSe material and are treated with double-sided solid coating to ensure excellent long-term durability. The service life of these lenses can be extended by more than 30%, and the replacement frequency is reduced by 50% compared to uncoated lenses.

● Wide Compatibility: These 20 mm laser focal lenses are designed to be compatible with CO2 laser engraving and cutting machines ranging from 30W to 90W. This versatility allows users to integrate them into various systems, including as replacements for K40 laser mirrors. This adaptability ensures that businesses can optimize their existing equipment without the need for extensive modifications.

● Easy Installation: The plano-convex shape of the lenses facilitates straightforward installation, enabling users to mount them in the correct orientation with ease.

Product Maintenance

● Regular Cleaning: Cleaning the lenses is vital to remove dust, fingerprints, and other contaminants that can affect laser performance. It is recommended to clean the lenses every 8 to 10 hours of use, or more frequently in dusty environments. Lenses kept clean maintain up to 99.5% transmittance, compared to a drop to around 90% for lenses with significant contamination. To clean, use an air bulb to blow off loose debris, followed by a lens tissue dampened with acetone, ensuring no streaks are left behind.

● Proper Handling: Handling the lenses with care is essential to avoid scratches and damage. Lenses subjected to improper handling experienced a 25% reduction in optical performance. Always hold lenses by the edges, and avoid touching the optical surfaces. When not in use, store the lenses in protective cases to prevent accidental scratches.

● Environmental Considerations: Maintaining the lenses in a suitable environment can significantly impact their durability. Ideal storage conditions include low humidity and stable temperatures, as fluctuations can lead to condensation on the lens surface. Lenses stored in optimal conditions can last up to 50% longer than those exposed to varying environmental factors.

● Regular Inspection: Conducting regular inspections can help identify any signs of wear or damage early. Inspect the lenses for any visible scratches, chips, or coatings deterioration. Early detection can extend the life of the lenses by up to 30%, as timely maintenance can prevent more severe damage that may require costly replacements.

Technical Parameters

Details

● High-Quality ZnSe Crystal

Made from China PVD ZnSe material, it offers excellent optical properties and is resistant to up to 80W CO2 lasers.

● Superb Coating Process

Features a double-sided solid coating that reduces laser loss, with laser transmittance of up to 99.5%.

● High Precision Process

Utilizes an excellent substrate and precise sling, along with polishing and grinding processes, ensuring high temperature and laser resistance for a long working life.

Certifications

Hot Tags: laser engraving machine focusing lens, China laser engraving machine focusing lens manufacturers, suppliers, factory, Galvo Mirror, F-Theta Lens, Laser Engraving Machine Motherboard, , Laser Head, Optical Fiber Laser

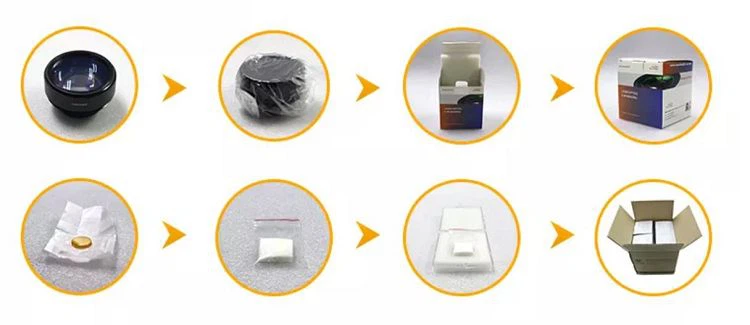

Compositions and Package

Main Accessories

FAQ

● About the Laser

What materials can I cut or engrave with a CO2 laser?

CO2 laser machine can cut, engrave, mark a wide range of non-metal and organic materials, such as acrylics, woods, plywood, MDF, paper, cardboard, fabrics, leather, glass, stone, ceramics, and more.

What materials can I cut or engrave with a Fiber laser?

Fiber Laser can cut, engrave, mark on metals, such as steel, stainless steel, aluminum, brass, copper, silver, gold, and on some non-metal polymers, wood, fabric.

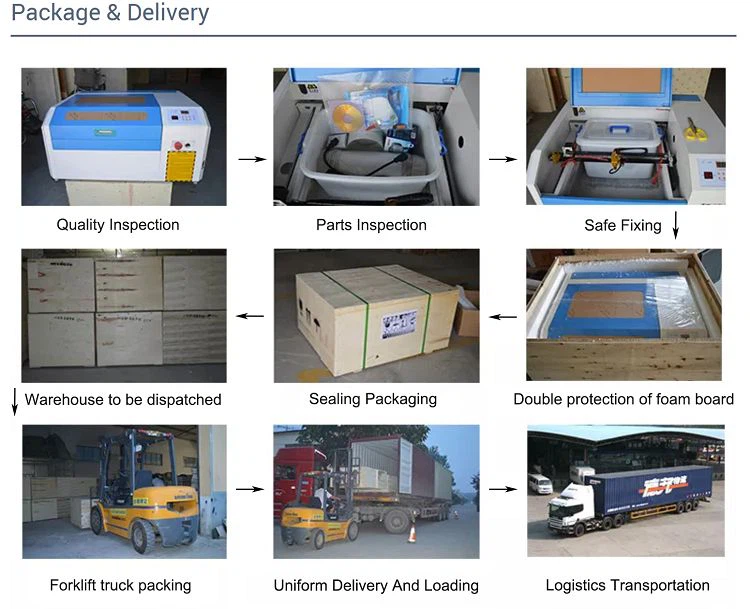

● Shipping

How is the machine packaged?

Laser equipment is shipped in a wooden box with Styrofoam to protect fragile parts

How long does it take to ship by air?

After we receive the order, send the machine to one of the main DHL, FEDEX and TNT offices in China. Smaller machines are shipped by courier service. Typically, it takes 10 to 14 days.

How long does it take to ship by sea?

Larger machines are shipped by sea. Usually, it takes 6 to 10 weeks. We can help you arrange delivery directly to your location.

● Customer Support

Is there a warranty?

Manufacturers extend the warranty on their devices to 18 months and replace parts at the factory purchase price.