Optical Fiber Laser

◆ A optical fiber laser can be defined as a solid-state laser that makes use of optical fibers as its active gain medium. A fiber made of glass silicate or phosphate absorbs unprocessed light from the pump laser diodes and converts it into a concentrated beam of a certain wavelength. The optical fiber is doped (incorporating a rare-earth element into the fiber) to make this possible. Different doping substances produce laser beams of differing wavelengths.

- Overview

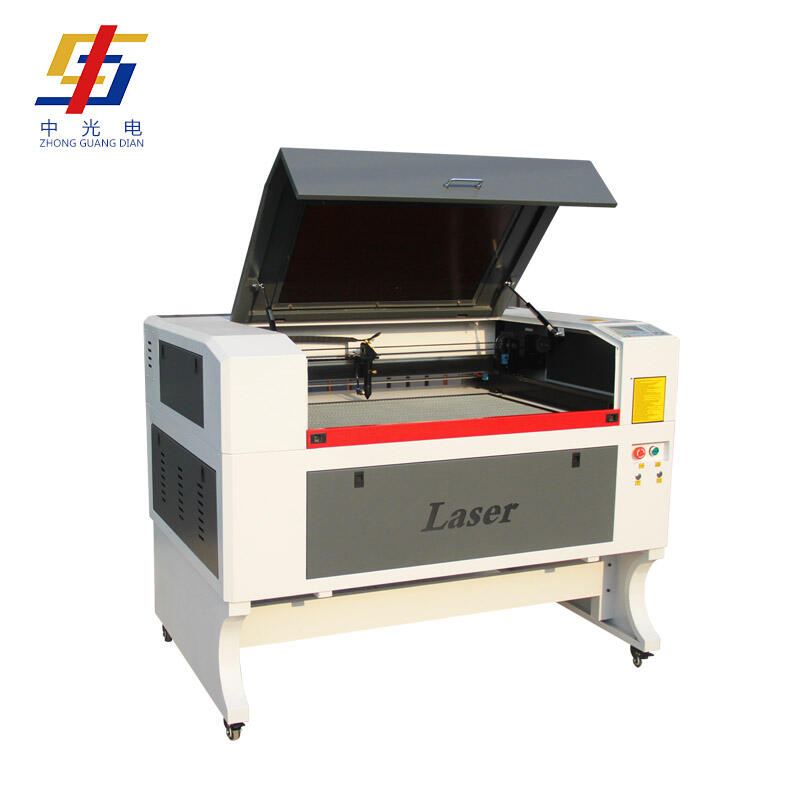

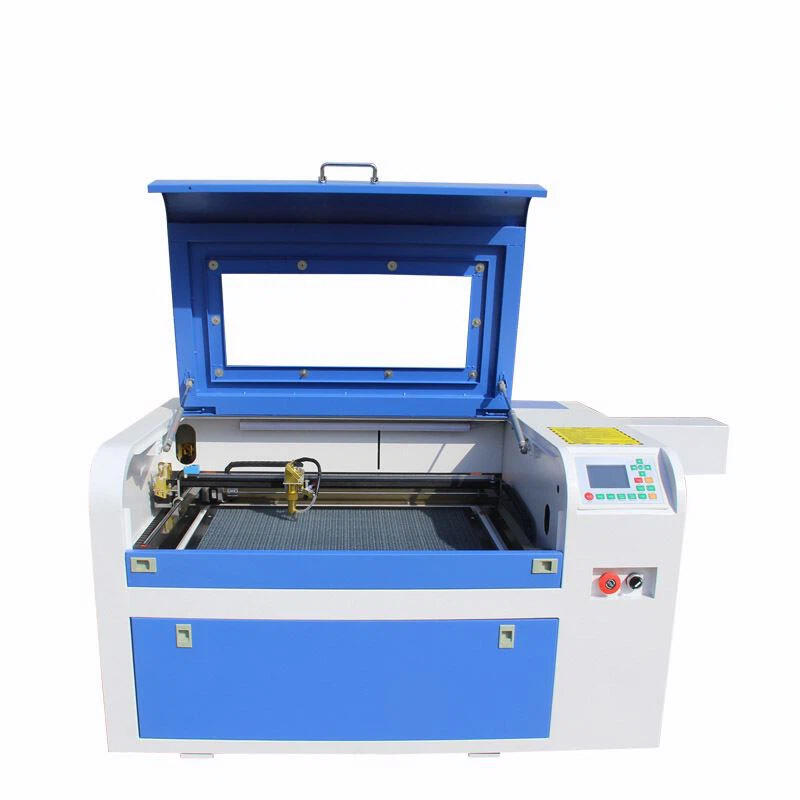

- Related Products

Hibo (Liaocheng High-tech Zone) Trading Co., Ltd

Haibo Laser is located in Liaocheng, a water city in Jiangbei known as the "Venice of North China". It is a high-tech enterprise specializing in the application of laser technology, customization, sales and service of laser equipment. We are committed to the production and research and development of laser products, and have obtained more than 20 invention patents.

Why Choose Us

● Rich Experience

Hibo Laser is a high-tech enterprise that focuses on laser technology. We specialize in customizing, selling, and servicing laser equipment. Our commitment to research and development has led to the creation of more than 20 patented inventions in the field of laser products.

● Our Products

We offer a range of products, including laser engraving, cutting, marking, and welding machines.

● Applications

Our products are widely used in various industries such as clothing and leather, trademark embroidery, advertising art, crafts, plexiglass, model manufacturing, packaging and printing, electronic appliances, hardware instruments.

● Our Services

We provide free proofing, guidance, and debugging after delivery. We also offer all necessary machine accessories, ensuring that you don't have to worry about after-sales support. We welcome you to visit our factory.

What is Optical Fiber Laser

A optical fiber laser can be defined as a solid-state laser that makes use of optical fibers as its active gain medium. A fiber made of glass silicate or phosphate absorbs unprocessed light from the pump laser diodes and converts it into a concentrated beam of a certain wavelength. The optical fiber is doped (incorporating a rare-earth element into the fiber) to make this possible. Different doping substances produce laser beams of differing wavelengths.

Advantages of Optical Fiber Laser

● Precision and Beam Quality

Optical fiber lasers are celebrated for their remarkable precision, making them ideal for tasks that require detailed and intricate cuts. The high beam quality of this particular laser allows for a finely focused spot, which results in sharp, clean edges with minimum material waste.

● Energy Efficiency

One of the standout features of optical fiber lasers is their exceptional energy efficiency. They achieve this by converting a large portion of electrical power into laser light, which significantly reduces energy waste. As a result, businesses see lower operational costs and a decreased carbon footprint.

● Versatility

Optical fiber lasers are ideal for marking a diverse array of materials, including metals like steel and aluminum, as well as non-metals like plastics and wood. Their precision and versatility make them the preferred choice for tasks that require detailed and durable marks.

● Compact Design

Featuring a smaller footprint than many other laser types, optical fiber lasers are known for their space-efficient design. This compact form factor allows them to fit easily into existing setups, even in facilities with limited space. Businesses benefit from this design as it not only conserves floor space but also simplifies integration into existing workflows.

● High Output Power

When tackling demanding tasks that need intense, focused energy, optical fiber lasers excel with their high output power. This feature allows for continuous operation at high power levels, delivering smooth, uninterrupted performance.

● Reliability and Low Maintenance

One of the biggest advantages of laser systems using fiber optics is how reliable they are with minimal upkeep. Thanks to their enclosed optical path, these lasers are shielded from dust and other particles, so you don't have to worry about frequent maintenance.

What Are the Types of Optical Fiber Laser?

Generally speaking, fiber lasers can be categorized using the following criteria:

● Laser source: Fiber lasers vary according to the material with which the laser source is mixed. Some examples include ytterbium-doped fiber lasers, thulium-doped fiber lasers, and erbium-doped fiber lasers. All these types of lasers are used for different applications because they produce different wavelengths.

● Mode of operation: Different types of lasers release laser beams differently. Laser beams can either be pulsed at a set repetition rate to reach high-peak powers (pulsed fiber lasers), as is the case with "q-switched", "gain-switched" and "mode-locked" lasers. Or, they can be continuous, meaning that they continuously send the same amount of energy (continuous-wave fiber lasers).

● Laser power: Laser power is expressed in watts and represents the average power of the laser beam. For example, you can have a 20W fiber laser, a 50W fiber laser, and so on. High-power lasers generate more energy faster than low-power lasers.

● Mode: The mode refers to the size of the core (where light travels) in the optical fiber. There are two types of modes: single-mode fiber lasers and multi-mode fiber lasers. The core diameter for single-mode lasers is smaller, typically between 8 and 9 micrometers, whereas it is larger for multi-mode lasers, typically between 50 and 100 micrometers. As a general rule, single-mode lasers convey laser light more efficiently and have a better beam quality.

How The Power of a Optical Fiber Laser Scales

Optical fiber lasers' ability to scale in power is constrained by Brillouin and Raman scattering as well as the short length of the lasers themselves. Many components, including amplifiers, switches, and logic elements, require nonlinear fiber configurations.

There are two classes of nonlinear effects in optical fibers. The first one is brought on by the Kerr effect, or the intensity dependence of the medium's refractive index. This phenomenon manifests as one of three effects, depending on the type of input signal: cross-phase modulation (CPM), self-phase modulation (SPM), or four-wave mixing (FWM).

The second nonlinear effect occurs when the optical field transfers some of its energy to the nonlinear medium via inelastic scattering. Such inelastic scattering can result in phenomena like stimulated Brillouin scattering (SBS) and stimulated Raman scattering (SRS).

Any form of stimulated scattering action can potentially be a source of gain for the fiber. In both processes, if the incident power rises above a specific threshold, the intensity of dispersed light increases exponentially. Because of the comparatively large frequency shift and the wider gain bandwidth, Raman amplification is more beneficial. The main distinction between them is that in Brillouin, the optical wave interacts with low-frequency acoustic phonons, whereas in Raman, the directed optical wave interacts with high-frequency optical phonons. Another key distinction is that SRS can happen in both directions while SBS only happens in the backward direction in optical fibers.

What's the Difference Between Optical Fiber Laser and CO2 Lasers?

The main difference between fiber and CO2 lasers is the source where the laser beam is created. In fiber lasers, the laser source is silica glass mixed with a rare-earth element. In CO2 lasers, the laser source is a mixture of gases which includes carbon dioxide.

While both types of lasers are very suitable for cutting materials, they actually have different functional emphasis. On one hand, CO2 lasers are very suitable tools to cut non-metallic materials such as plastics. Their relatively high efficiency and good beam quality make them the most widely used laser type in this industry.

On the other hand, fiber lasers have gained significant progress in cutting metal sheets (mainly stainless steel) in recent years, primarily due to their high cutting speed, which is often 2-3 times faster than CO2 lasers at the comparable power levels. Generally, when cutting metals with thickness of 0.25" and thinner, it is worth considering fiber lasers for mass production, but when the metal is thicker than 0.375", CO2 lasers still enjoy the speed advantage and superior cutting qualities. Thus, it is unlikely for fiber lasers to completely replace the CO2 lasers for material cutting.

Application of Optical Fiber Laser

● Laser Marking

1064 nm emission wavelength ytterbium-doped fiber lasers are considered ideal for laser marking applications. These lasers may leave sharp, durable imprints on plastic and metal surfaces. They can be customized to accommodate quick production cycles and can be manual or automated. Fiber laser equipment can be used to anneal, etch, and engrave as well.

● Laser Welding

Another important application for these lasers is in welding services. Optical fibre laser welding is one of the most promising upcoming technologies that is gaining market share fast due to the various benefits the process offers. Laser welding provides faster speeds, greater precision, lower deformation, higher quality and efficiency compared to traditional methods.

● Laser Cleaning

Laser cleaning the process of removing paint, oxide, and rust from metal surfaces, works best using optical fiber lasers. The procedure can be automated and customized for various manufacturing line conditions.

● Laser Cutting

Laser cutting is one of the most researched areas of optical fibre laser application. It can handle complex cuts with impressive edge quality. This makes it optimal for parts with close tolerances. Its adoption is increasing across the board with fabricators due to its long list of benefits.

How Long Does a Optical Fiber Laser Last?

Most online sources claim that fiber lasers last 100,000 hours whereas CO2 lasers last 30,000 hours. This is not entirely true. These numbers refer to a value called "mean time between failures" (MTBF), which isn't the same for all fiber lasers. In reality, you will see different numbers for different types of fiber lasers.

The MTBF measures the reliability of a laser by indicating how many hours the laser is expected to function before a failure occurs. It is obtained by testing multiple laser units, and then dividing the total number of operational hours by the total number of failures. Although this value does not exactly tell you how long a fiber laser can last, it still provides a good idea of the laser's reliability.

Which Materials can be Processed With Optical Fiber Lasers?

Optical fiber lasers are ideal for processing a wide range of materials and with years of industrial use have proven reliability. Fiber lasers are especially popular for processing metals. The type of metal involved is of secondary importance. Fiber lasers can process mild steel, stainless steel, titanium, iron and nickel as well as reflective metals such as aluminum, brass, copper and precious metals (silver and gold). They also work well with materials that have anodized and painted surfaces. Fiber lasers, and particularly pulsed nanosecond lasers, are also used in processing silicon, gemstones (including diamonds), plastics, polymers, ceramics, composites, thin layers, bricks, and concrete.

A optical fiber laser works by using an optical fiber as a resonator to amplify the laser beam. This is done by producing an overlapping structure of fiber cladding doped with Yb ions. A laser diode excitation is then pumped inside the fiber to generate a high-output laser. In turn, the laser is optimal for deep engraving, annealing, and cutting – especially for large production batches of repeated tasks that need quick completion.

However, due to the high output of heat produced by fiber lasers, they may not be the ideal choice for marking on non-metals. Some non-metals have very low melting points, meaning that fiber lasers could disrupt their structural integrity by melting beyond the target area. On the other hand, other non-metals have high melting points that combat the fiber's beam. With the high melting point, the fiber laser may not be able to achieve the preferred darkest mark. In these cases, alternative laser types may be a better option.

How to Maintain Optical Fiber Laser

Regular inspection is a key part of optical fiber laser maintenance. This includes checking key components such as power lines, light bulbs, filters, and sensors. The connection of the power line should be firm and not loose; the light bulb is an important part of the lighting equipment and needs to be replaced regularly; the filter is an important component for filtering dust and impurities and needs to be cleaned or replaced regularly; the sensor is an important component for monitoring the status of the equipment. It needs to be calibrated or replaced regularly.

During maintenance, safe operation is crucial. First, make sure the device is turned off and unplugged to avoid accidental electric shock or damage to the device. Non-professionals should never attempt repairs by themselves to avoid unnecessary losses and risks. At the same time, during the maintenance process, it is recommended to record the steps and results of the maintenance to facilitate future maintenance and management and provide reference and assistance to other maintenance personnel.

To reduce optical fiber laser power attenuation issues, regular preventive maintenance is recommended. This includes regular inspections and cleaning of equipment, identifying and solving potential problems promptly to ensure stable equipment operation. Preventive maintenance not only extends the service life of equipment but also improves equipment operating efficiency.

In addition to maintaining the equipment itself, it is also essential to keep its surrounding environment tidy. Dust and dirt can negatively affect the performance of your device and may even cause it to malfunction. Therefore, the equipment and its surroundings should be cleaned regularly to ensure no dust and dirt accumulation. At the same time, keep the temperature and humidity of the environment where the equipment is located appropriate to maintain the optimal operating condition of the equipment.

With the continuous advancement of technology, the software and hardware of optical fiber lasers are also constantly updated. To maintain device performance and compatibility, related software and hardware should be updated promptly. This not only improves the operating efficiency of the equipment but also enhances its stability and reduces the possibility of failure.

FAQ

Q: What are the limitations of optical fiber lasers?

Q: How many hours does a optical fiber laser last?

Q: What frequency should a optical fiber laser be set at?

Q: Do optical fiber lasers lose power over time?

Q: What are the failure modes of optical fiber lasers?

Q: How accurate is a optical fiber laser?

Q: Which is better optical fiber laser or CO2 laser?

Q: Do optical fiber lasers need ventilation?

Q: What humidity should a optical fiber laser be?

Q: Do optical fiber lasers need to warm up?

Q: Can you cut with a optical fiber laser?

Q: Does optical fiber laser need gas?

Q: What are the two types of optical fiber lasers?

Q: Do you need eye protection for optical fiber laser?

Q: Do optical fiber lasers emit radiation?

Q: What is the tolerance of a optical fiber laser?

Hot Tags: optical fiber laser, China optical fiber laser manufacturers, suppliers, factory, CO2 Mixed Laser Cutting Machine, CO2 Laser Cutting Machine For Non metallic, Silicon Laser Cutting Machine, laser cutting machine for fabric and leather, CO2 Glass Tube Laser Marking Machine, Fiber Optical Laser Scanning Welding Machine

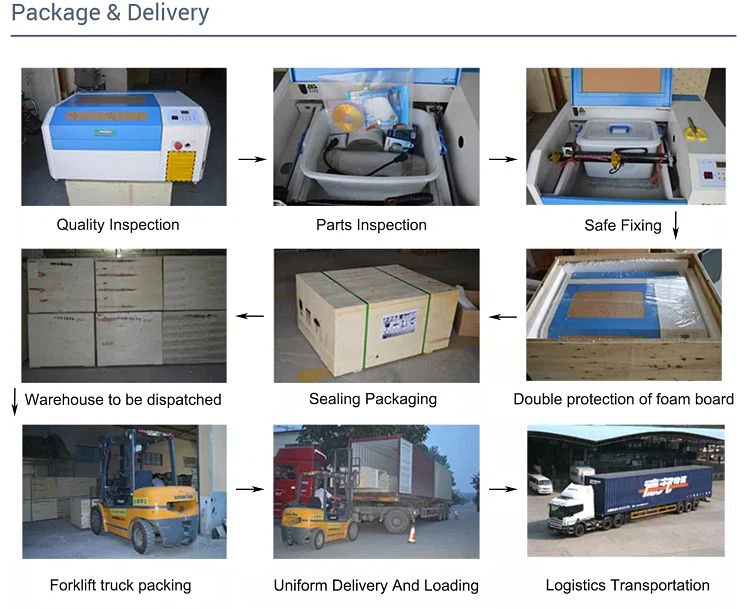

Compostions and Package