1000w Laser Cutting Machine

◆ 1000w Laser Cutting Machine Model: HB-HJ 1000/1500/2000;

◆ Laser power: 1000W/1500W/2000W;

◆ Welding speed:0-120mm/s;

◆ Working voltage: (220V or 380V) ±10% 50HZ/60HZ;

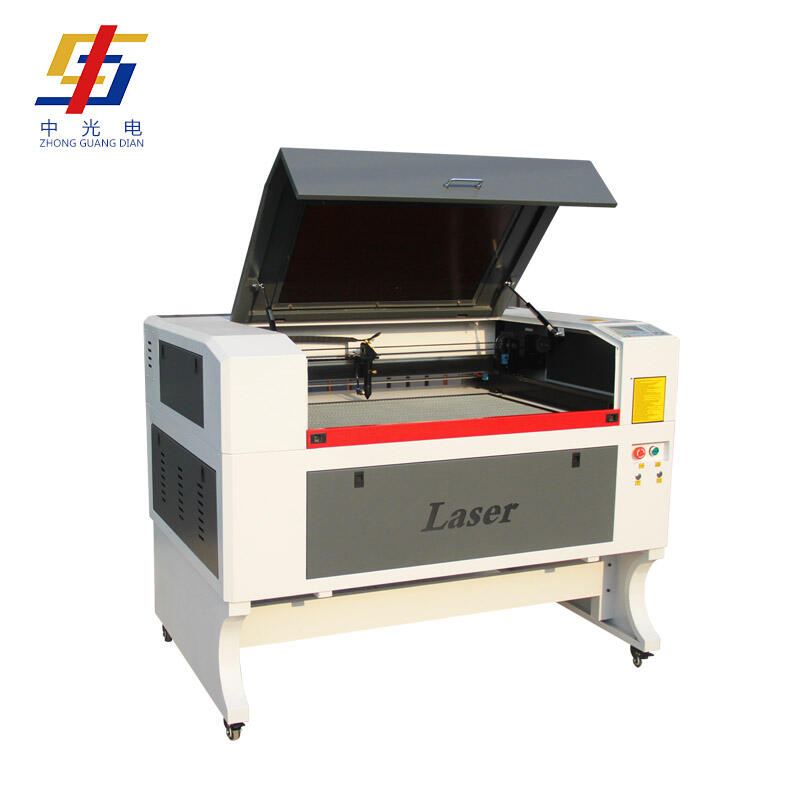

- Overview

- Related Products

Introduction

A 1000W laser cutting machine is a powerful tool that employs a focused laser beam to cut through various materials, including metal, wood, and plastic. Its significant power enables precise and efficient cutting, making it suitable for industrial applications such as fabrication, signage, and artistic endeavors. The machine delivers clean edges and minimizes material waste.

Advantages

1. Versatility and Flexibility

A key feature of a 1000W laser cutting machine is its ability to process a diverse range of materials and thicknesses. These machines can easily cut metals such as steel, aluminum, copper, and brass, along with non-metallic materials like plastics, wood, and ceramics. For example, a manufacturer might utilize a 1000W laser cutter to produce intricate metal components for automotive applications while also crafting custom wooden signs, showcasing its adaptability for various projects.

2. Precise Control and High-Speed Cutting

Thanks to advanced technology, a 1000W laser cutting machine provides precise control and high-speed cutting capabilities, allowing it to manage complex shapes and intricate designs effortlessly. This versatility is especially beneficial for prototyping, small-scale production, and custom manufacturing across different industries. For instance, a jewelry designer can employ a laser cutter to create detailed patterns and designs on metal or acrylic, resulting in unique, high-quality pieces.

3. Reduced Material Waste

Laser cutting is recognized for its minimal kerf, which means the cut width is extremely narrow. This characteristic significantly reduces material waste compared to traditional cutting methods. Manufacturers can optimize their raw material usage, leading to cost savings and a more environmentally friendly production process. For example, a furniture manufacturer can use a 1000W laser cutter to design and cut intricate shapes from wood sheets, optimizing the layout to minimize scrap.

4. Enhanced Safety Features

Modern 1000W laser cutting machines come equipped with a variety of safety features that ensure operator safety during use. These features include protective enclosures, automated shut-off mechanisms, and advanced ventilation systems to manage fumes and particles. By prioritizing safety, manufacturers can protect their workers while boosting productivity. For example, an automotive parts supplier can implement a 1000W laser cutting machine with robust safety features, enabling operators to concentrate on their tasks without unnecessary risk.

Applications

1. Metal Processing

These machines excel at cutting complex shapes and designs from metal sheets, tubes, and profiles. In metal processing, laser cutting machines are essential for producing precision parts with tight tolerances. For instance, a manufacturer might use a 1000W laser cutter to fabricate intricate components for industrial machinery, ensuring that the parts meet exact specifications and quality standards.

2. Automotive Industry

The automotive sector relies heavily on 1000W laser cutting machines due to their ability to accurately and efficiently cut sheet metal parts, chassis components, and body panels. These machines facilitate the production of lightweight and durable parts, which are critical for modern vehicles. For example, automotive manufacturers can employ laser cutting to create complex geometries for vehicle frames, enhancing both performance and fuel efficiency.

3. Aerospace Industry

In the aerospace sector, 1000W laser cutting machines are used to manufacture various aircraft parts, including structural components, engine parts, and interior accessories. The precision and repeatability of laser cutting make it ideal for producing lightweight and robust parts that comply with strict safety regulations. For instance, aerospace manufacturers can utilize laser cutting to create intricate wing structures, ensuring they are both aerodynamic and structurally sound.

4. Electronics Manufacturing

The electronics industry greatly benefits from 1000W laser cutting machines for producing circuit boards, housings, and other components. These machines enable the precise cutting of intricate designs necessary for electronic devices, ensuring high-quality performance and reliability. For example, a smartphone manufacturer may use laser cutting to create detailed patterns on circuit boards, facilitating better connectivity and functionality.

Application Materials

Stainless steel, Carbon steel, galvanized sheet, iron, aluminum alloy, copper and so on

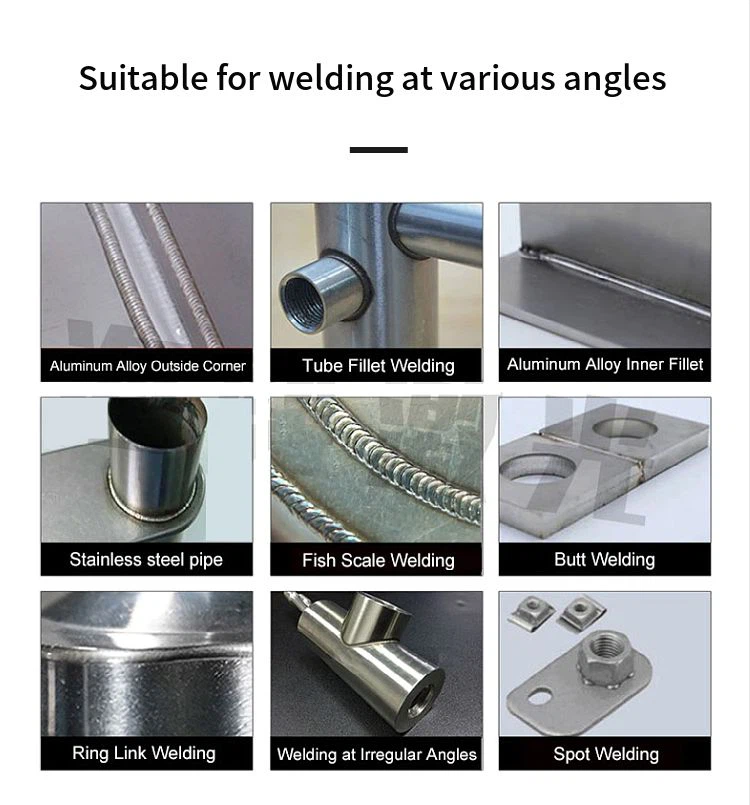

It's suitable for welding at various angels.

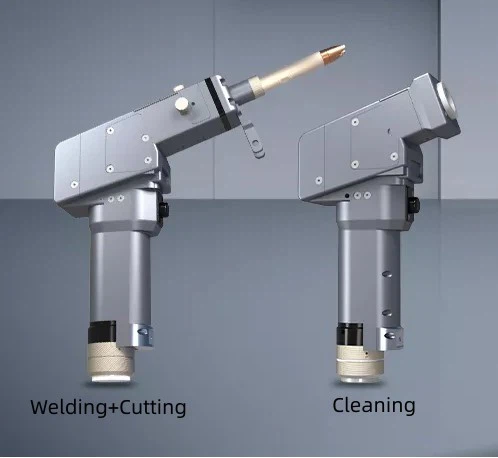

The hanheld laser machine can weld, cut and clean stainless steel, Carbon steel, galvanized sheet, iron, aluminum alloy, copper and so on by 2 different laser heads.

Technical Parameters

| Model | HB-HJ1000/1500/2000 |

| Laser Power | 1000W/1500W/2000W |

| Fiber Length | 10 meter (standard),15 meter (optional) |

| Working Way | Continuous/Modulated Pulse |

| Welding Speed | 0mm-120mm/S |

| Chiller | Dual temperature and control chiller |

| Applicable plate thickness | 0-10mm |

| Gap Requirements | 0mm-2mm |

| Voltage | AC220V±10% 50HZ/AC380V±10% 50HZ |

| Item Weight | About 240kg |

Details

● Famous Fiber Laser Source

Raycus is the most famous laser souce in China. It has a long warranty of 2 years. High electro-optic conversion rate and stable beam.

● High Quality laser cutting head

We use famous brand laser cutting haed. The nozzle is made of copper. The 1000W laser cutting machine uses red point positioning to make the welding position is more accurate.

● Different Nozzles Are Available.

There are many different nozzles to cut and weld different materials at various angles.

● Wire feeding device (optional)

Optional automatic wire feeding device Software controlled, adjustable wire feed speed Filling the welding seam and increasing the welding strength

● Automatic Wire Feeder

The 1000W laser cutting machine equipped with automatic wire feeder. It is controled by software to adjust thee feeding speed.

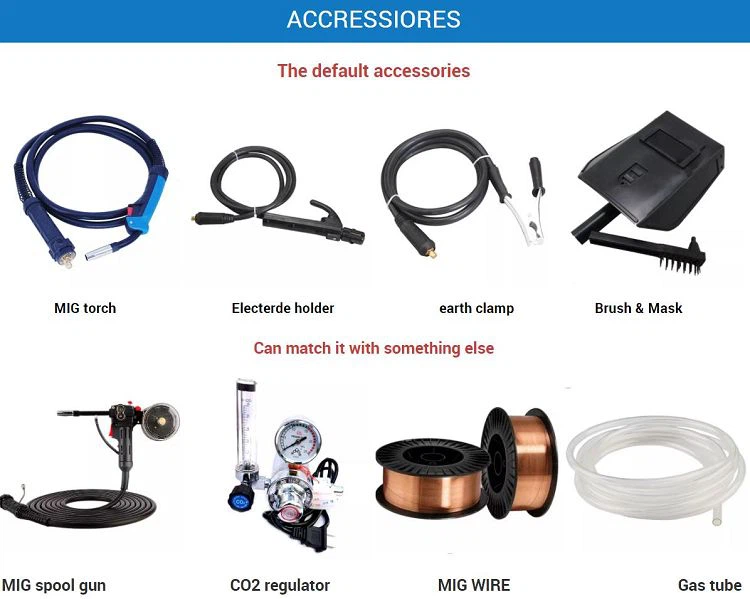

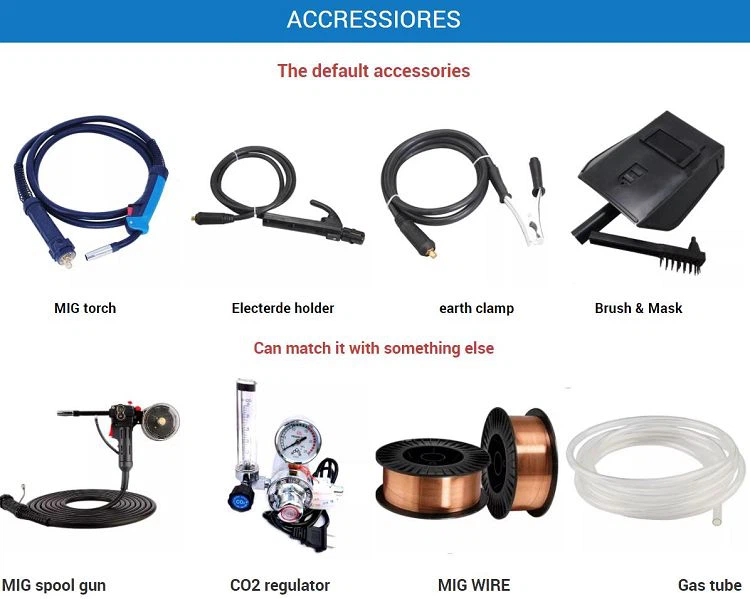

Accessories Shipped with the Machine

Packaging Process

Factory And Exhibition

Certifications

Hot Tags: 1000w laser cutting machine, China 1000w laser cutting machine manufacturers, suppliers, factory, automotive laser welding machine, CNC Gantry laser welding machine, Spot Laser Welding Machine, laser welding machine for glasses, Fiber Hand held Laser Welding Machine, Automatic Laser Welding Machine

Compositions and Package

Main Accessories

FAQ

● About the Laser

What materials can I cut or engrave with a CO2 laser?

CO2 laser machine can cut, engrave, mark a wide range of non-metal and organic materials, such as acrylics, woods, plywood, MDF, paper, cardboard, fabrics, leather, glass, stone, ceramics, and more.

What materials can I cut or engrave with a Fiber laser?

Fiber Laser can cut, engrave, mark on metals, such as steel, stainless steel, aluminum, brass, copper, silver, gold, and on some non-metal polymers, wood, fabric.

● Shipping

How is the machine packaged?

Laser equipment is shipped in a wooden box with Styrofoam to protect fragile parts

How long does it take to ship by air?

After we receive the order, send the machine to one of the main DHL, FEDEX and TNT offices in China. Smaller machines are shipped by courier service. Typically, it takes 10 to 14 days.

How long does it take to ship by sea?

Larger machines are shipped by sea. Usually, it takes 6 to 10 weeks. We can help you arrange delivery directly to your location.

● Customer Support

Is there a warranty?

Manufacturers extend the warranty on their devices to 18 months and replace parts at the factory purchase price.