3D Laser Marking Machine

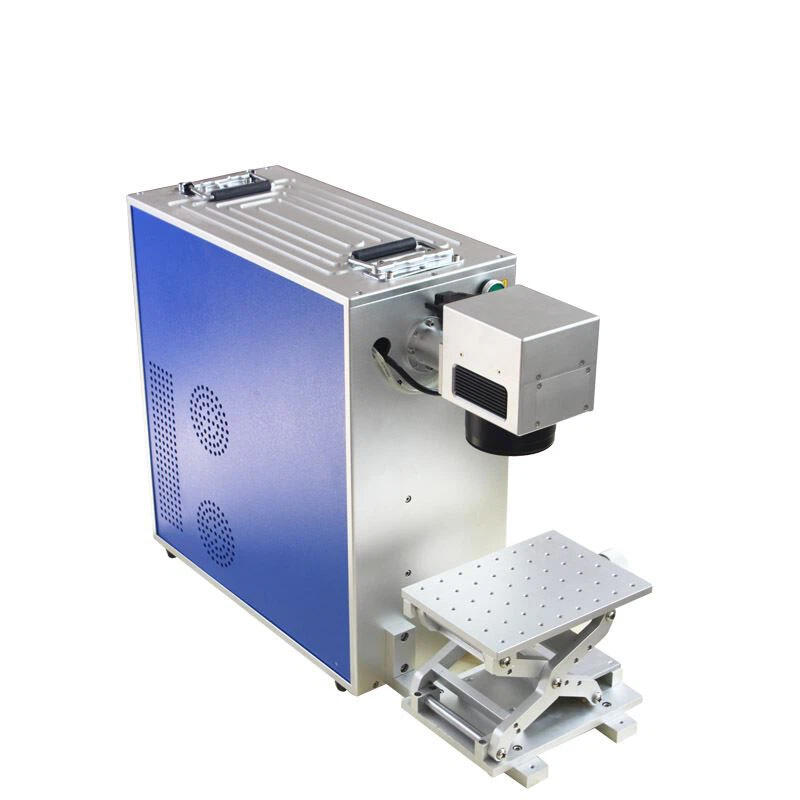

◆ 3D laser marking machine is a type of 5 axis laser engraving system that uses an advanced front focusing method to control and move the dynamic focus lens with 3D marking software, and perform variable beam expansion before the laser is focused, thereby changing the focal length of the laser beam. Realize precise engraving of text, symbols and patterns on the 3D surface. It is also known as 3D laser engraving machine, 3D laser texturing machine, 5 axis laser engraving machine, 5 axis laser marking machine.

- Overview

- Related Products

Hibo (Liaocheng High-tech Zone) Trading Co., Ltd

Haibo Laser is located in Liaocheng, a water city in Jiangbei known as the "Venice of North China". It is a high-tech enterprise specializing in the application of laser technology, customization, sales and service of laser equipment. We are committed to the production and research and development of laser products, and have obtained more than 20 invention patents.

Why Choose Us

● Rich Experience

Hibo Laser is a high-tech enterprise that focuses on laser technology. We specialize in customizing, selling, and servicing laser equipment. Our commitment to research and development has led to the creation of more than 20 patented inventions in the field of laser products.

● Our Products

We offer a range of products, including laser engraving, cutting, marking, and welding machines.

● Applications

Our products are widely used in various industries such as clothing and leather, trademark embroidery, advertising art, crafts, plexiglass, model manufacturing, packaging and printing, electronic appliances, hardware instruments.

● Our Services

We provide free proofing, guidance, and debugging after delivery. We also offer all necessary machine accessories, ensuring that you don't have to worry about after-sales support. We welcome you to visit our factory.

What is 3D Laser Marking Machine

3D laser marking machine is a type of 5 axis laser engraving system that uses an advanced front focusing method to control and move the dynamic focus lens with 3D marking software, and perform variable beam expansion before the laser is focused, thereby changing the focal length of the laser beam. Realize precise engraving of text, symbols and patterns on the 3D surface. It is also known as 3D laser engraving machine, 3D laser texturing machine, 5 axis laser engraving machine, 5 axis laser marking machine.

Advantages of 3D Laser Marking Machine

● Flexibility

The 3D laser marking machine can mark various shapes and sizes of curved products, such as oblique planes, segment gaps, stepped surfaces, cylinders, circular cones, and spheres. lt can also mark different depths of the product, allowing for greater design flexibility. This allows companies to mark more intricate patterns and graphics on their products, which can help them attract customers.

● Handle curved surfaces

Another significant advantage of 3D laser marking machine is its ability to handle curved surfaces. Unlike traditional 2D fiber lasers, which require complex adjustments to perform curved engraving, the 3D laser marking machine can trace the focus of deep curves in real-time. This can greatly improve the processing efficiency and accuracy of curved surfaces.

● Handling large format products

In addition to its ability to mark curved surfaces, the 3D laser marking machine can handle large-format products, and it is very efficient in terms of production speed. This is because the 3D laser marking machine can quickly change the focal length of the laser beam and adjust its position, thereby allowing it to process more workpieces in less time.

● Easy to use

The 3D laser marking machine is easy to use and is compatible with most popular software systems. lt can be used in all kinds of production line, visual positioning, deep-carving and other applications. The 3D laser marking machine can be configured to meet the requirements of a variety of materials, such as metals, plastics, glass, and wood.

How 3D Laser Marking Machine Works

3D laser marking machine is the use of high energy density laser to partially irradiate the workpiece to make the surface material vaporize or undergo a chemical reaction of discoloration, thereby leaving a permanent mark. 3D laser marking machine can mark various characters, symbols and patterns, etc., and the character size can even reach the micron level.

The laser beam used for laser marking is generated by a laser, undergoes a series of optical transmission and processing, and finally is focused by an optical lens, and then deflects the focused high-energy beam to a designated position on the surface of the processed object to form a permanent concave mark.

The traditional 2D laser marking machine adopts the post-focus method, which generally only allows plane marking within the specified range. The emergence of the new 3D laser marking machine has solved the long-term inherent defects of the 2D laser marking machine.

The working principle of candlelight imaging is to control and move the dynamic focusing mirror through software, and to expand the variable beam before laser focusing, so as to change the focal length of the laser beam and achieve precise surface focusing processing of objects at different heights.

The Difference Between 3D Laser Marking Machine and 2D Laser Marking Machine

● The scope of application is different: Traditional 2D laser marking machines can only perform flat marking, while 3D laser marking machines can mark or engrave on 3D objects such as curved surfaces and irregular surfaces. Achieve a more three-dimensional and fine marking effect.

● The marking effect is different: 2D laser marking machine can only do monochrome outline marking; 3D laser marking machine can achieve richer patterns and effects, such as deep engraving, embossing, color filling, etc.

● Different processing efficiency: Traditional 2D laser marking machines are more suitable for batch processing of materials, and can only mark on one plane at a time. For marking with different depths and heights, it is necessary to switch the processing area multiple times, which takes a long time. The 3D laser marking machine can achieve continuous processing in three-dimensional space through height adjustment during the processing process, and the processing efficiency is higher.

● Different cost: Due to the technology, 3D laser marking machines are usually more expensive than 2D laser marking machines, so for customers who need higher accuracy and wider application, choosing 3D laser marking machines may be a better choice.

Application of 3D Laser Marking Machine

Manufacturing is one of the most common applications of 3D laser marking machines. This technology can be used to label and label products during the manufacturing process.Whether in automobile manufacturing, electronic equipment production or aerospace industry, 3D laser marking machine can achieve high-precision lettering and marking to ensure product quality and traceability.

The medical industry is also an important application field for 3D laser marking machines. The application of laser technology in medical equipment manufacturing and medical device labeling is becoming increasingly popular. Laser marking can provide permanent identification on medical equipment to ensure product traceability and anti-counterfeiting.

The third application area is the jewelry and luxury goods industry. In this industry, the quality and uniqueness of products are crucial. 3D laser marking machines can be used to make small and delicate markings on jewelry and luxury goods to prove their authenticity and uniqueness. This technology can achieve personalized labeling of gold and silver jewelry, watches, bags, and other luxury goods, providing consumers with more reliable purchasing protection.

Another important application area is the protection of art and cultural heritage. The 3D laser marking machine can make small and precise markings on the surface of cultural relics, providing important information about age,manufacturing location,and owner. This helps researchers, collectors, and cultural heritage protection institutions to trace and protect cultural relics. The 3D laser marking machine can be used to mark and protect cultural relics and artworks.

3D laser marking machines also play an important role in the aerospace industry. Accurate marking and identification are crucial for traceability and quality control in aerospace manufacturing processes. Laser marking technology can be used for engraving, serial number marking, and QR code identification on aviation components to ensure the safety and traceability of aircraft.

Suitable Materials for 3D Laser Marking Machine

● Hardwood

There is the most common 3D laser marking machine materials. It is well-suitable due to its aesthetics. While the material is burnt during the process, cleaning is easy using water.

● Acrylic

This is the second most common material for the process. It is harder than wood. However, it has a good impressive melting point. As a result, it is capable of 3D laser marking machine.

● Medium Density Fiberboard (MDF)

MDF is the perfect material if you are looking for a material you can mark and paint later. It is soft, affordable, and accessible.

● Metals

Metals such as aluminum, stainless steel, copper, etc., are also compatible with 3D laser marking machine. They are the second most common 3D laser marking machine materials.

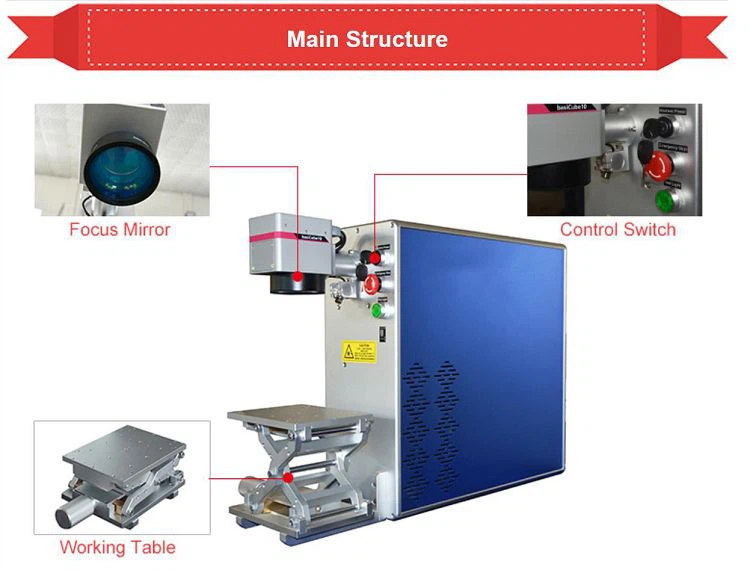

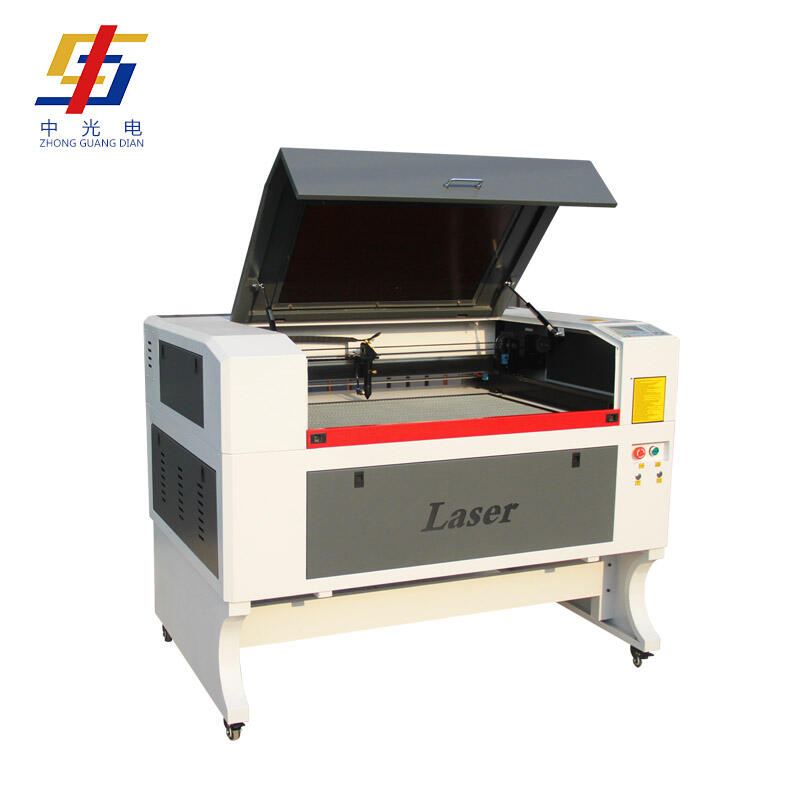

Components of 3D Laser Marking Machine

● Laser Source: The core component that generates the laser beam. Common types include fiber lasers, CO₂ lasers, and UV lasers, depending on the material being marked.

● Galvoscanner: This component is responsible for directing the laser beams' movement. It provides rapid and precise scanning across the material's surface. It ensures efficient and accurate marking.

● Focus Control System: Ensures that the laser beam stays focused on the surface of the material, even when marking objects with varying heights or complex shapes.

● Control Software: The software interface that allows users to input marking parameters, designs, and adjust settings for depth, power, and speed.

● Workstation: This component is a stable platform for the material being marked. It ensures proper positioning and stability during the laser marking process. The dimension of this component varies based on ● different models from the manufacturer.

● Lens: Directs and focuses the laser beam onto the marking surface, ensuring precision and clarity.

Factors to Consider When Selecting 3D Laser Marking Machine

● The Power Of The Laser

The power of the laser is measured in watts (W). The longer the wattage, the more influential the laser. For most applications, a laser with a power of 30W is more than sufficient. However, if you're looking to mark metals or other rigid materials, you may need a laser with a higher power.

● The Wavelength Of The Laser

The wavelength of the laser is measured in nanometers (nm). The shorter the wavelength, the more precise the laser beam will be. Many lasers marking machines come with a wavelength of 1064nm. The 1064nm wavelength is ideal for most marking applications.

● The Spot Size Of The Laser Beam

The spot size is measured in micrometers (μm). The smaller the spot size, the more precise the laser beam will be. Some laser marking machines have a spot size of less than 10μm. That's incredibly precise! As you can see, there are many factors to consider when choosing a laser marking machine. But once you understand what you need, you should be able the find out the perfect device for your application.

● The Marking Area Of The Machine

The marking area is measured in millimeters (mm). The larger the marking area, the more materials you'll be able to mark at one time. An industrial laser marking machine typically has a marking size of 300mm x 300mm. Other devices may have a smaller or larger marking area.

● The Type Of Laser Marking Machine

There're two main types of 3D laser marking machines: desktop and industrial. Desktop machines are smaller and more affordable, while industrial machines are larger and more powerful. You should choose the type of machine based on your specific needs. A desktop machine will be more than sufficient if you're only looking to mark small items. But an industrial machine will be necessary if you want to keep more oversized items.

● Safety Features

Given the nature of 3D laser marking machines, there's always a risk of fire. Enclosed machines equipped with fire alarms and smoke purifiers are ideal.

● Material Compatibility

Define the materials you want to use. Different 3D laser marking machines excel at engraving different materials. Make sure the machine you choose is compatible with production efficiency and the materials you plan to use.

How to Maintain 3D Laser Marking Machine

Over time, dust, debris, and other contaminants can accumulate on the laser lens, reducing its efficiency and accuracy. To maintain optimal performance, clean the lens regularly using a microfiber cloth or specialized lens cleaning solution. Ensure that the cleaning is done gently to avoid scratching the lens surface.

The marking head, axis rails, and any other moving parts require proper lubrication to avoid wear and tear. Use the recommended lubricant to keep these parts functioning smoothly. Regularly inspect these areas and lubricate them as per the manufacturer's guidelines to prevent friction and extend the machine's lifespan.

The machine's performance can be enhanced by keeping its software and firmware up to date. Regularly check for updates from the manufacturer and install them to benefit from new features, bug fixes, and performance improvements. Updated software can also ensure better compatibility with newer operating systems and 3D design files.

The laser source is the most critical component of the 3D laser marking machine. Periodically check the power output and performance of the laser. If you notice any reduction in marking quality or power, consult the manufacturer's guidelines on adjusting or replacing the laser source.

Periodically inspect all electrical connections and the power supply to ensure they are secure and free from wear. Loose or damaged connections can cause power fluctuations that may affect the performance of the machine or even lead to damage.

FAQ

Q: Do you need to passivate after 3D laser marking machine?

Q: How long does 3D laser marking machine marking last?

Q: How do you maintain a 3D laser marking machine?

Q: How does a 3D laser marking machine work?

Q: What PPE is required for 3D laser marking machine?

Q: How do I choose a 3D laser marking machine?

Q: What is the difference between 3D laser marking and laser engraving?

Q: What is the difference between 20W and 30W 3D laser marking machine?

Q: What does a 3D laser marking machine do?

Q: What is the difference between 3D laser marking machine and other laser marking machines?

Q: How does 3D laser marking improve product traceability?

Q: How accurate are the markings made by a 3D laser marking machine?

Q: What is the average lifespan of a 3D laser marking machine?

Q: What software is used with 3D laser marking machines?

Q: How does a 3D laser marking machine improve efficiency in production?

Hot Tags: 3d laser marking machine, China 3d laser marking machine manufacturers, suppliers, factory, li ion battery laser welding machine, Wood Plank Laser Cutting Machine, Metal And Non-metal Laser Cutting Machines, Three Station Automatic Laser Marking System, Laser Engraving Machine for Wine Bottle, YAG Laser Cutting Machine

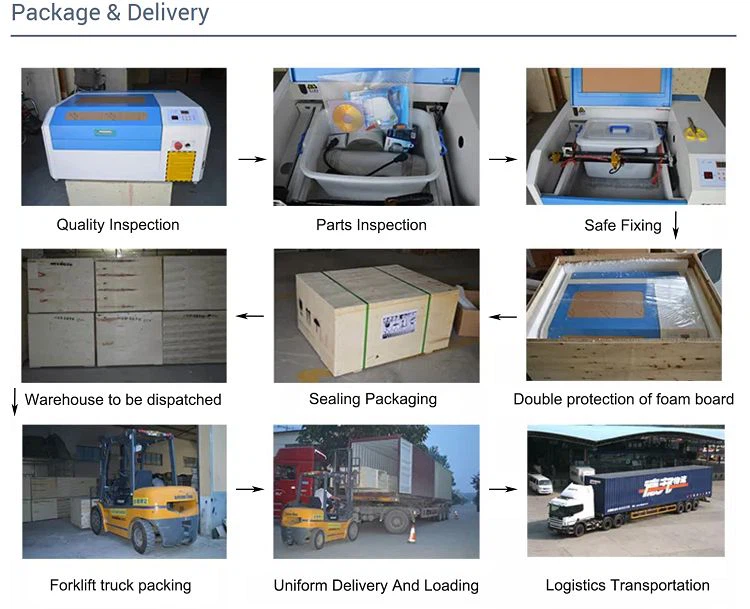

Compostions and Package