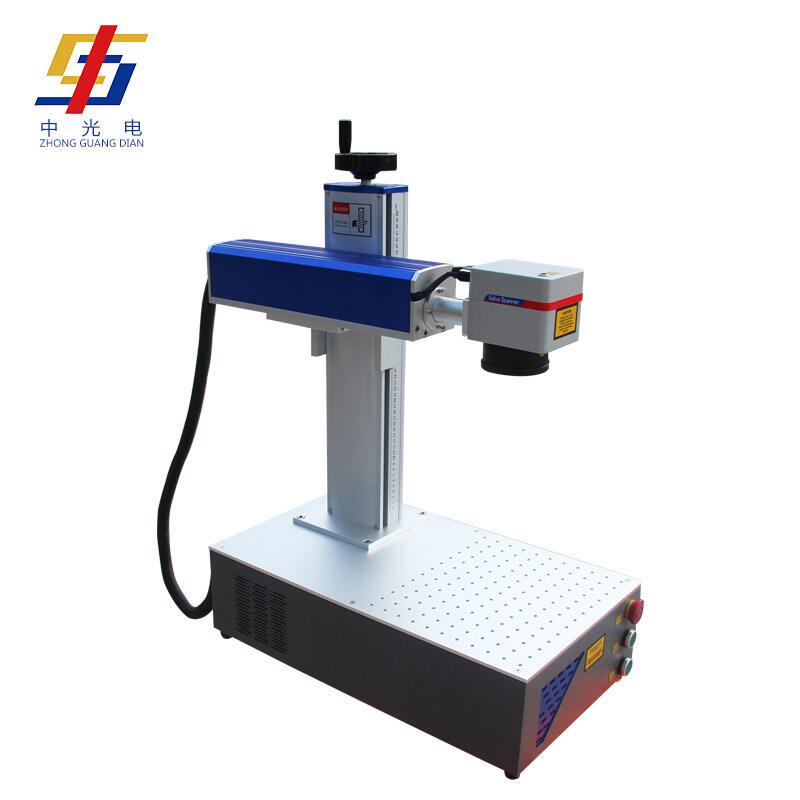

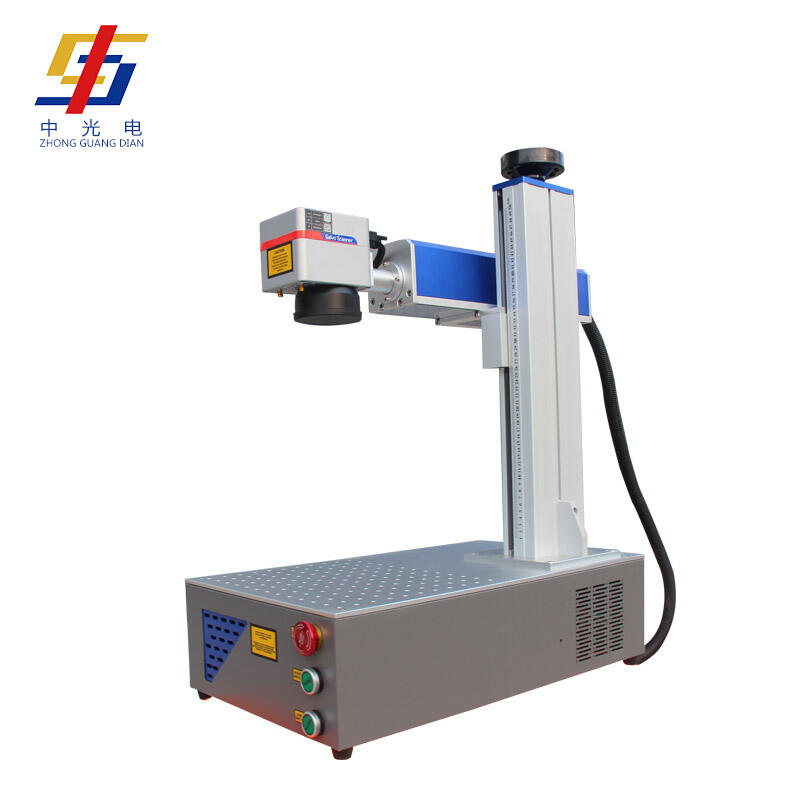

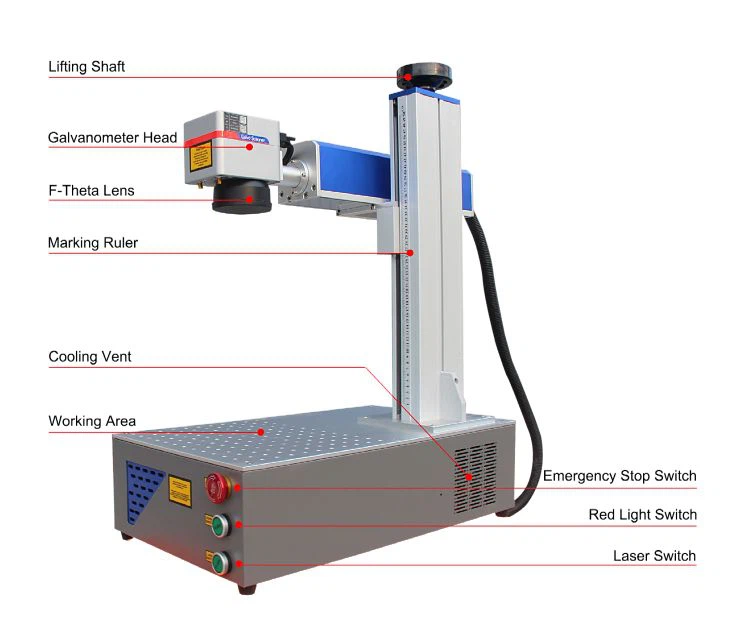

50W Deep Metal Laser Engraving Machine

◆ 50W Deep Metal Laser Engraving machine;

◆ Model: HB Optical Fiber Marking Machine;

◆ Laser type: Fiber laser;

◆ Laser power: 20W/30W/50W;

◆ Working Area: 110mm*110mm;

◆ Working voltage: (220V or 110V) ±10% 50HZ/60HZ.

- Overview

- Related Products

Introduction

The 50W deep metal laser engraving machine is a powerful tool featuring an ergonomic design. It utilizes an upward focusing mode, enabling operators to work comfortably and significantly minimizing fatigue during extended use. The machine incorporates double-layer closed dust-proof patented technology, ensuring maintenance-free operation. With advanced laser technology, it produces deep and intricate markings, making it ideal for industrial applications such as part and brand identification.

Feature

● No Manual Adjustment Required

The 50W deep metal laser engraving machine removes the necessity for manual adjustments, such as focusing and alignment. This automated system streamlines the setup process, enabling operators to concentrate on their tasks instead of dedicating time to detailed calibrations.

● Automatic Height Adjustment

Featuring a unique control system, this machine can automatically engrave at varying heights on the workpiece surface in a single operation. This capability boosts productivity by minimizing setup time and ensuring consistent engraving quality across different materials and thicknesses.

● User-Friendly Operator Interface

The operator interface is designed for ease of use, allowing for straightforward navigation and control of the engraving process. This feature promotes efficient operations, enabling users to adapt to a range of tasks and achieve high-quality results with minimal training.

● Fast Marking Speed

This machine offers a high marking speed, significantly enhancing throughput. Such efficiency is essential for businesses aiming to meet tight deadlines and improve production capabilities without compromising quality.

● Strong Anti-Interference Ability

The 50W deep metal laser engraving machine is designed with robust anti-interference capabilities, ensuring reliable performance even in demanding environments. This stability leads to consistent engraving results, minimizing the risk of errors and material waste.

● Enhanced Processing Feasibility

Together, these features provide a high degree of feasibility for efficient and flexible processing. Operators can seamlessly manage various engraving tasks, adapting effortlessly to changes in workload and project demands.

Applications

1. Component Numbering for Inventory Management

Laser engraving is an efficient way to add identification numbers to various components and parts. This technique streamlines inventory management and enhances assembly accuracy by minimizing human error. For example, manufacturers can engrave unique serial numbers onto mechanical components, making tracking and retrieval straightforward. Additionally, businesses aiming to improve brand visibility can incorporate logos and names into their products using laser engraving. This not only increases product awareness but also strengthens brand identity in a competitive marketplace.

2. Labeling in the Medical Industry

Regulatory compliance is crucial in the medical sector. Laser engraving offers a dependable means of inscribing identification information on medical devices and equipment, including surgical instruments and diagnostic tools. For instance, patient-specific details can be engraved on implants to ensure proper identification and usage. This degree of traceability assists companies in adhering to strict regulatory standards while enhancing patient safety, thus reducing the likelihood of medical errors.

3. Marking Automotive Parts

The automotive sector significantly benefits from laser engraving technology. Manufacturers utilize 50W deep metal laser engraving machines to mark vital components such as engine parts, chassis, and transmissions. For instance, a car manufacturer may engrave part numbers or barcodes on engine components to enhance quality control measures. This approach facilitates part tracking throughout the supply chain, helping to prevent expensive recalls and ensuring that each vehicle complies with safety and quality standards.

4. Tool and Mold Manufacturing

Precision is essential in tool and mold manufacturing, where intricate designs and fine details are critical for producing high-quality products. Laser engraving enables the creation of molds, dies, and tools with complex patterns and specifications. For example, a company that manufactures plastic injection molds can use laser engraving to apply detailed markings or logos directly onto the mold surface. This process guarantees that each item produced meets the necessary specifications and improves the overall quality of the final product.

5. Electronic Manufacturing

In electronic manufacturing, laser engraving is commonly employed to mark components, circuit boards, and connectors. The durability and high contrast of laser markings ensure that information such as part numbers and manufacturer logos remains clear throughout the product's lifespan. For example, an electronic device manufacturer might engrave model numbers on circuit boards, making identification and maintenance support easier. This technique provides consistent and enduring results, which are vital for preserving brand integrity and ensuring customer satisfaction.

Technical Parameters

| Model | HB optical fiber marking machine |

| Laser Type | Fiber Laser |

| Working area | 110*110/150*150/200*200/300*300mm |

| Laser power | 20W/30W/50W |

| Laser wavelength | 1060nm |

| Beam quality | m² <1.5 |

| Application | metal and nonmetal |

| Marking Depth | ≤1.2mm |

| Marking Speed | 800 standard characters/second |

| Minimum Character | 0.15mm |

| Repeated Precision | ±0.003mm |

| Focus Spot Diameter | <0.01mm |

| Communication Interface | USB |

| Working voltage | 220V±10% 50HZ,110V±10% 60HZ |

| Cooling Mode | Air Cooling |

| Supported graphic formats | AI, BMP,DST,DWG,DXF,DXP,LAS,PLT |

| Controlling software | EZCAD |

| Working temperature | 15°C-45°C |

| Resolution ratio | <4500DPI |

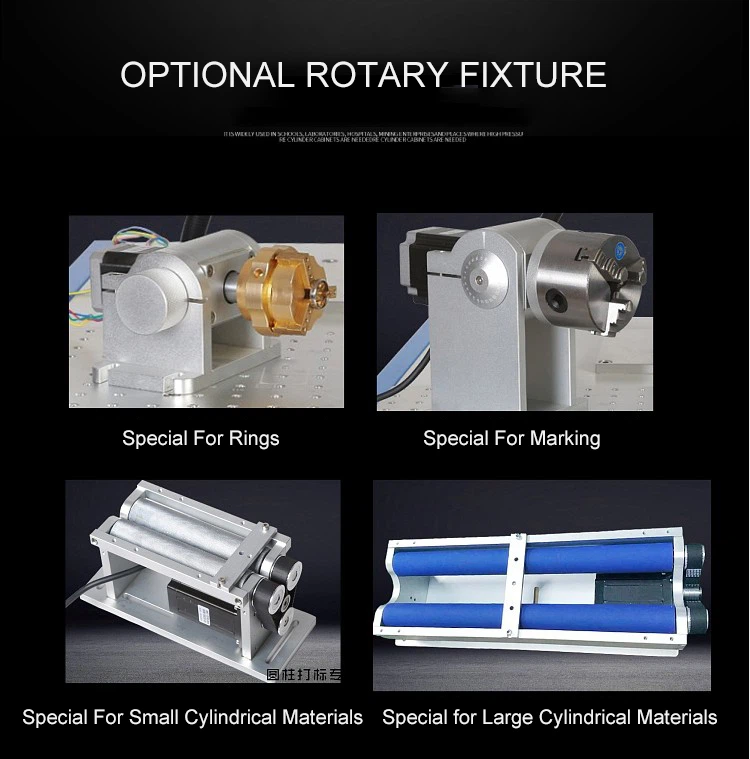

| Optional parts | Rotary Device, Lift platform, other customized Automation |

| Color | Blue and white |

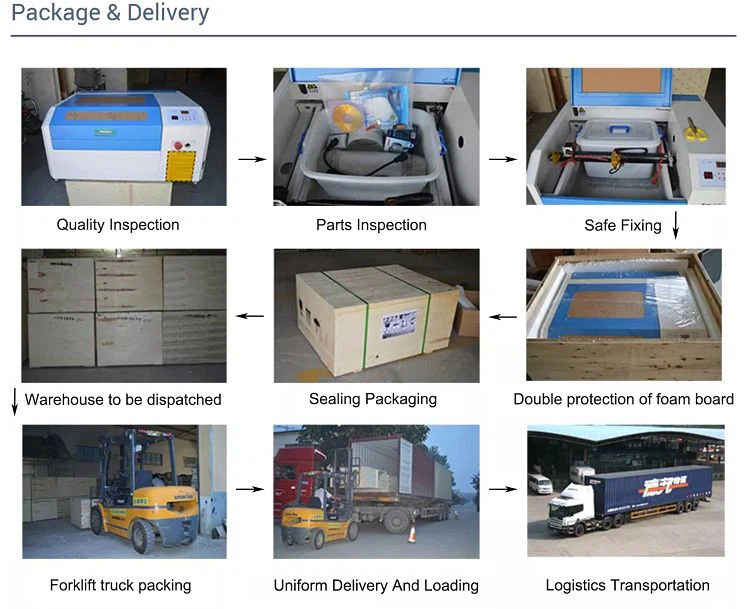

| Package | Plywood |

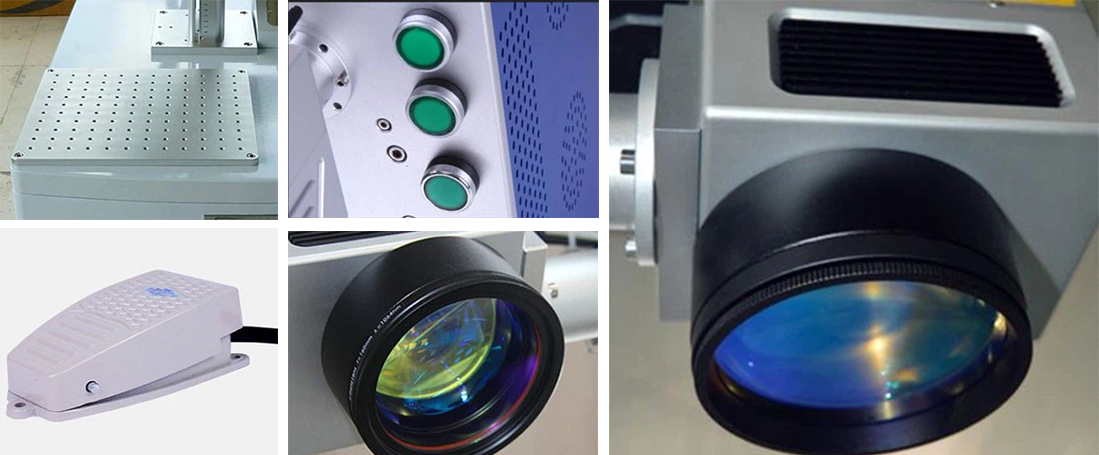

Details

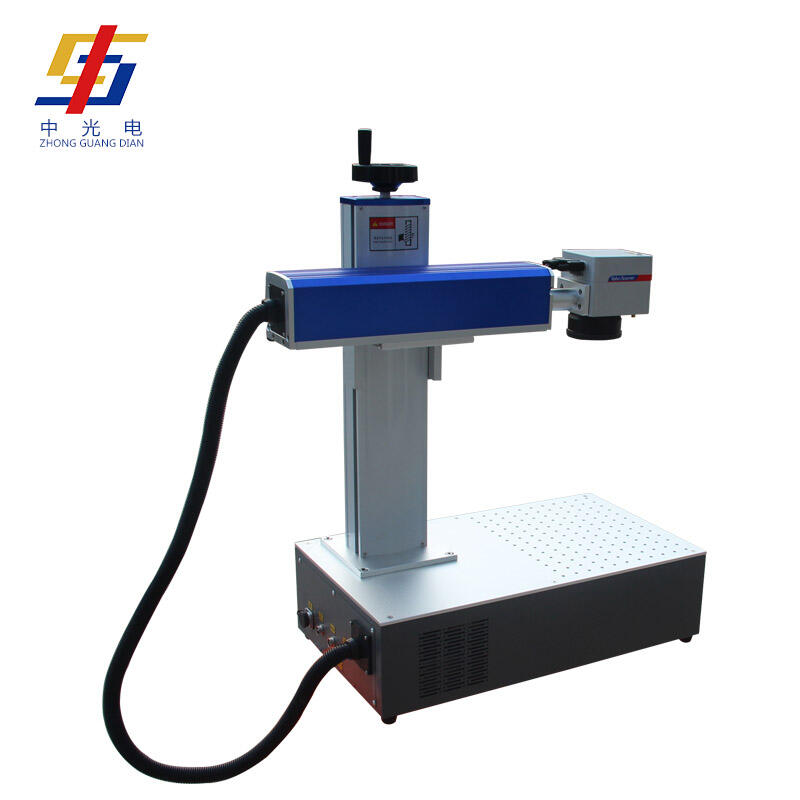

● F-Theta Lens

High quality field lens, focus on the spot, uniform and dense, high transmittance, strong laser resistance, fine marking.

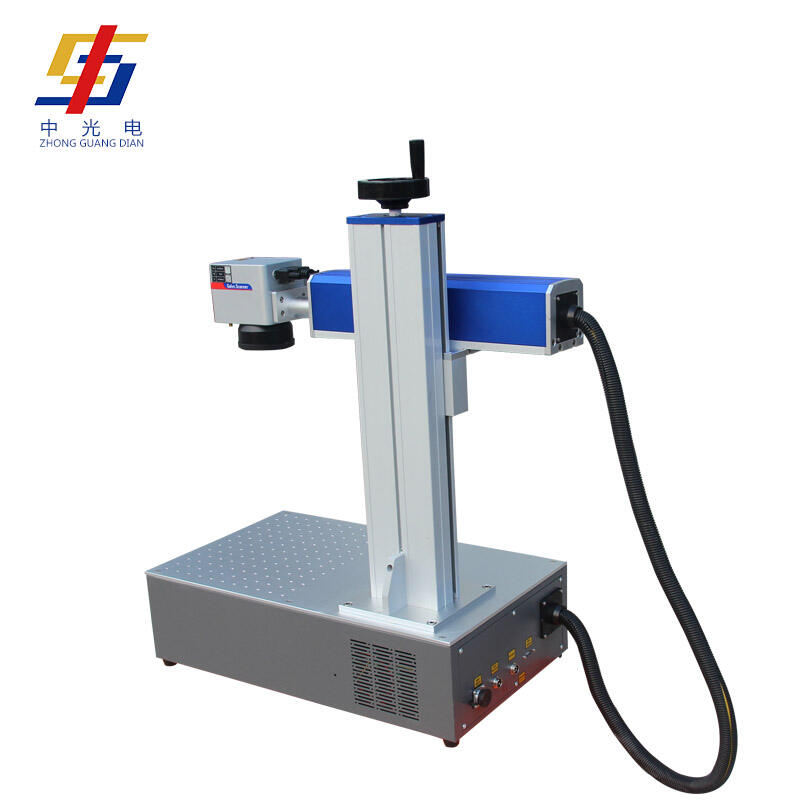

● Galvanometer Scanner

Use high speed galvo scanner which has good running stability, high positioning accuracy, fast marking speed, strong anti-interference ability, it has reached the international leading level in this field.

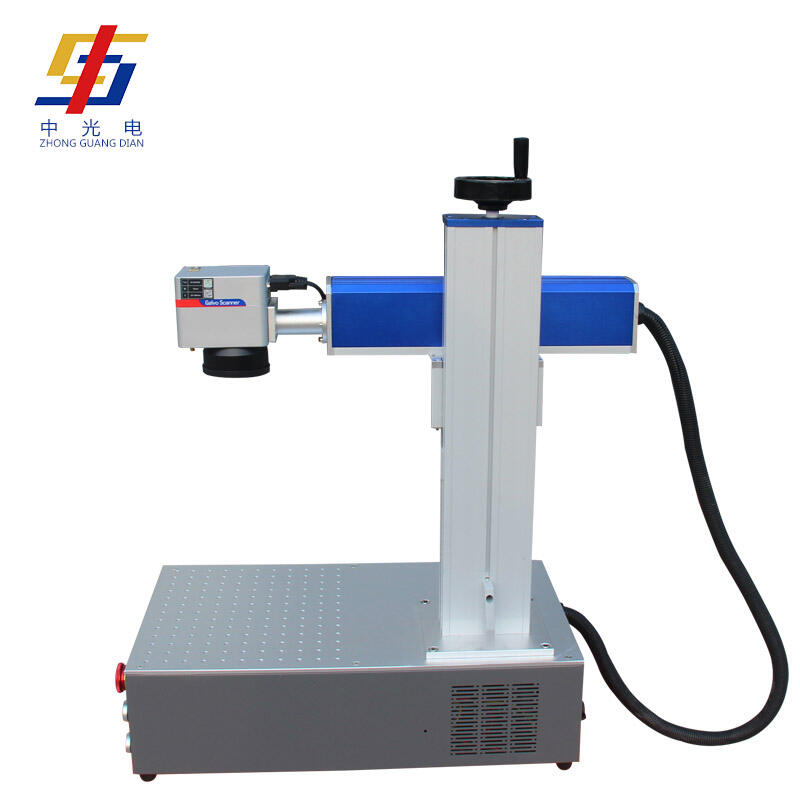

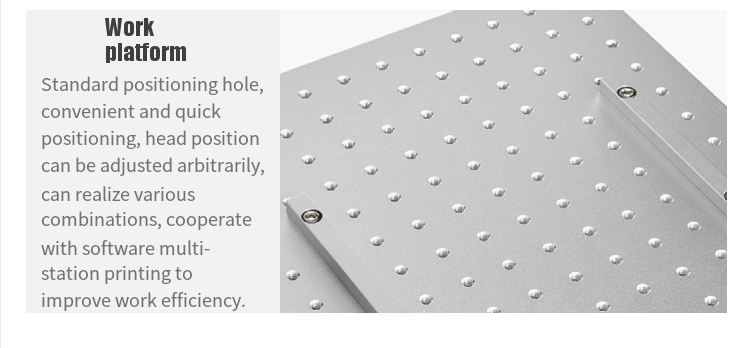

● Aluminum Marking Platform

Big size support max 300x300 marking size, the locating hole and positioning block makes the target easily, and the marking is more accurate.

● Control button

Humanized control system, easy to operate, safe and convenient, dust proof design.

● Foot Pedal

Easy to operate, improve the working speed of bulk marking.

Factory And Exhibition

Hot Tags: 50w deep metal laser engraving machine, China 50w deep metal laser engraving machine manufacturers, suppliers, factory, Laser Engraving Stainless Steel Marking Machine, XY Slide Automatic Laser Marking Machine, CO2 Glass Tube Laser Marking Machine, Double sided Fiber Laser Marking Machine, Beverage packaging laser marking machine, Autofocus Fiber Laser Engraving Machine

Compositions and Package

Main Accessories

FAQ

About the Laser

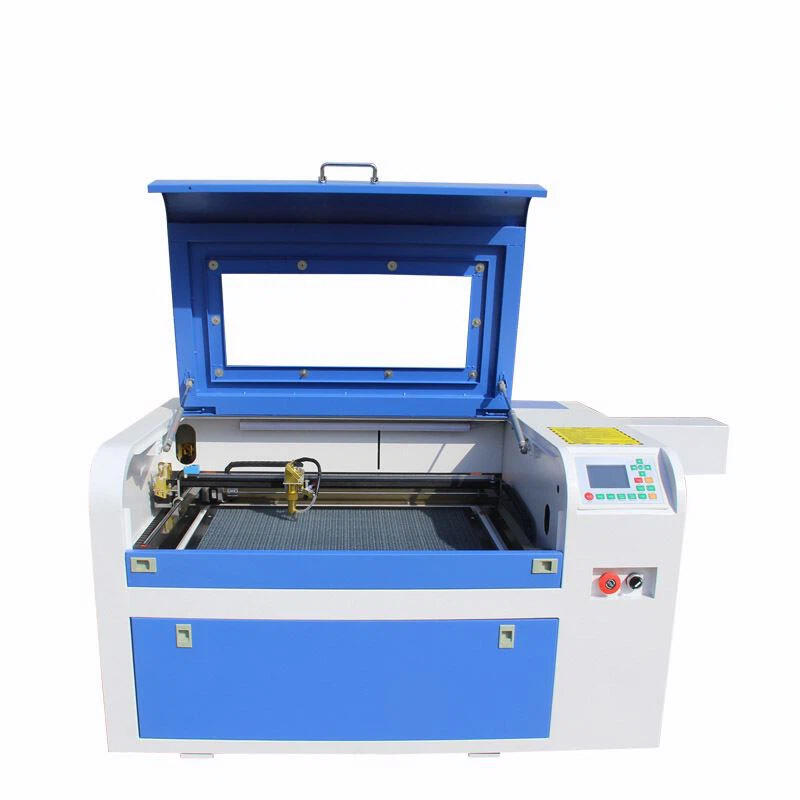

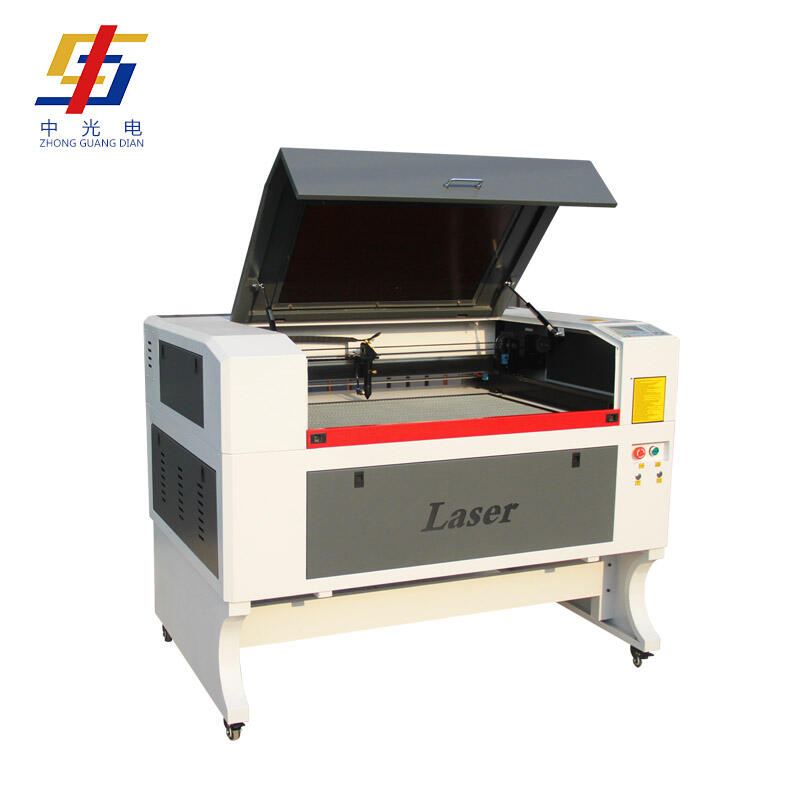

What materials can I cut or engrave with a CO2 laser?

CO2 laser machine can cut, engrave, mark a wide range of non-metal and organic materials, such as acrylics, woods, plywood, MDF, paper, cardboard, fabrics, leather, glass, stone, ceramics, and more.

What materials can I cut or engrave with a Fiber laser?

Fiber Laser can cut, engrave, mark on metals, such as steel, stainless steel, aluminum, brass, copper, silver, gold, and on some non-metal polymers, wood, fabric.

Shipping

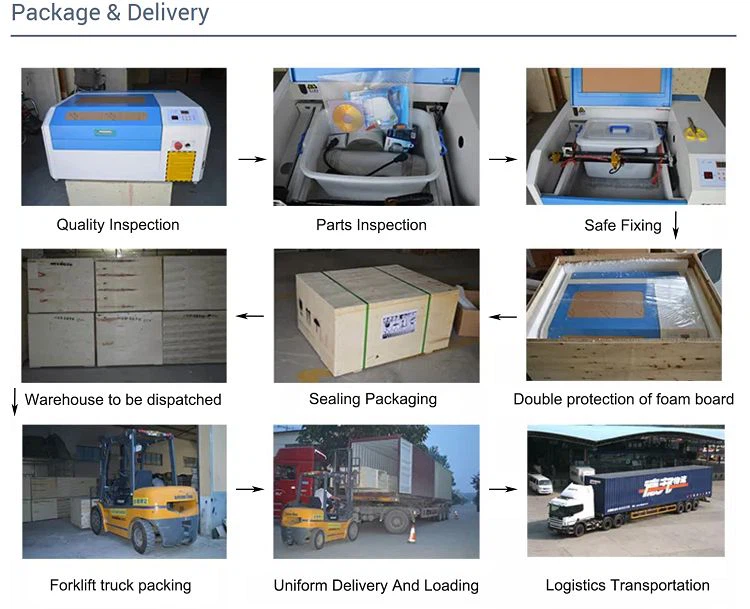

How is the machine packaged?

Laser equipment is shipped in a wooden box with Styrofoam to protect fragile parts

How long does it take to ship by air?

After we receive the order, send the machine to one of the main DHL, FEDEX and TNT offices in China. Smaller machines are shipped by courier service. Typically, it takes 10 to 14 days.

How long does it take to ship by sea?

Larger machines are shipped by sea. Usually, it takes 6 to 10 weeks. We can help you arrange delivery directly to your location.

Customer Support

Is there a warranty?

Manufacturers extend the warranty on their devices to 18 months and replace parts at the factory purchase price.