Model

Desktop Dot Peen Marking Machine

◆ Desktop Dot Peen Marking Machine;

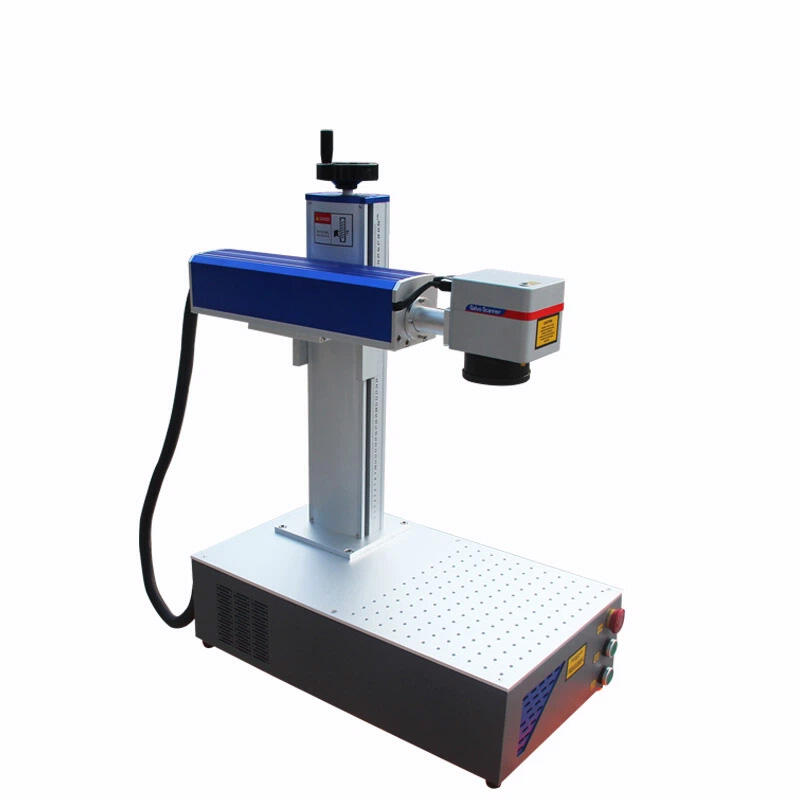

◆ Model: HB Optical Fiber Marking Machine;

◆ Laser type: Fiber laser;

◆ Laser power: 20W/30W/50W;

◆ Marking speed:800 standard characters/s;

◆ Working voltage: (220V or 110V)±10% 50HZ/60HZ.

- Overview

- Related Products

Application Materials

Introduction

Desktop dot peen marking machines are compact, automated devices that utilize a stylus pen to create precise, permanent marks on various materials. They provide an efficient and cost-effective solution for marking and identifying solid materials, including metals like steel and aluminum, as well as plastics. As a result, they are widely used in industries such as manufacturing, electronics, and automotive.

Advantages

1. Cost-Effectiveness

A key advantage of dot peen marking machines is their cost-effectiveness. When compared to other marking methods like laser or chemical etching, the initial investment in a dot peen marking machine is relatively low. This affordability makes it an appealing choice for small to medium-sized businesses seeking a reliable marking solution without significant financial strain.

2. Versatility and Precision

Dot peen marking systems are exceptionally versatile, able to mark a broad range of materials, including metals, plastics, and ceramics. These machines provide impressive precision, capable of marking surfaces with hardness levels of up to 62 HRC. For example, in the automotive sector, manufacturers frequently utilize dot peen marking to generate precise identification codes on engine components, ensuring compliance with industry standards and facilitating traceability.

3. High-Speed Marking

Another major benefit of dot peen marking machines is their high-speed operation. These systems can quickly mark parts and products, significantly boosting productivity in manufacturing settings. For instance, in high-volume production lines, the ability to swiftly mark components can enhance throughput and minimize downtime, making it an effective solution for busy operations.

4. Easy to Use and Maintain

Designed with user-friendliness in mind, dot peen marking machines require minimal training for operators. Their integrated software streamlines the marking process, while maintenance is straightforward, requiring fewer consumables than other marking technologies. This simplicity in use and maintenance makes them an attractive option for businesses aiming to optimize their operations.

5. Cross-Industry Application

Dot peen marking machines have a wide range of applications across various industries. They are commonly utilized in sectors such as medical equipment, military hardware, aerospace, and electronics. For instance, within the aerospace industry, dot peen marking is essential for part identification and traceability, ensuring that all components can be monitored throughout their lifecycle.

6. Durable Marking

The markings produced by dot peen marking machines are highly durable and resistant to wear, corrosion, and fading. This durability is crucial in industries where components may be subjected to harsh conditions. For example, in the oil and gas sector, the resilience of the marks guarantees that identification remains clear, even in extreme environments.

7. Customization Options

Dot peen marking machines provide numerous customization options for marking patterns, fonts, and sizes. This flexibility allows businesses to create unique markings tailored to their specific requirements. For example, a manufacturer can easily alternate between different marking styles to suit various products without needing to invest in additional equipment.

8. Environmentally Friendly

In contrast to some other marking methods that may involve toxic chemicals or hazardous materials, dot peen marking is an environmentally friendly choice. It generates no harmful fumes and does not require consumables that necessitate disposal, making it a safer option for both operators and the environment.

9. Enhanced Traceability

In today's manufacturing landscape, traceability is essential for maintaining quality control and ensuring regulatory compliance. Dot peen marking allows manufacturers to embed QR codes or barcodes directly onto their products, enabling easy tracking throughout the supply chain. This feature is especially advantageous in industries where quality assurance is critical.

Technical Parameters

parameter:

|

|

HB optical fiber marking machine |

|

Laser Type |

Fiber Laser |

|

Working area |

110*110/150*150/200*200/300*300mm |

|

Laser power |

20W/30W/50W |

|

Laser wavelength |

1060nm |

|

Beam quality |

m²<1.5 |

|

Application |

metal and nonmetal |

|

Marking Depth |

<1.2mm |

|

Marking Speed |

800 standard characters/second |

|

Minimum Character |

0.15mm |

|

Repeated Precision |

±0.003mm |

|

Focus Spot Diameter |

<0.01mm |

|

Communication Interface |

USB |

|

Working voltage |

220V±10%50HZ,110V±10%60HZ |

|

Cooling Mode |

Air Cooling |

|

Supported graphic formats |

AI,BMP,DST,DWG,DXF,DXP,LAS,PLT |

|

Controlling software |

EZCAD |

|

Working temperature |

15°C-45°C |

|

Resolution ratio |

<4500DPI |

|

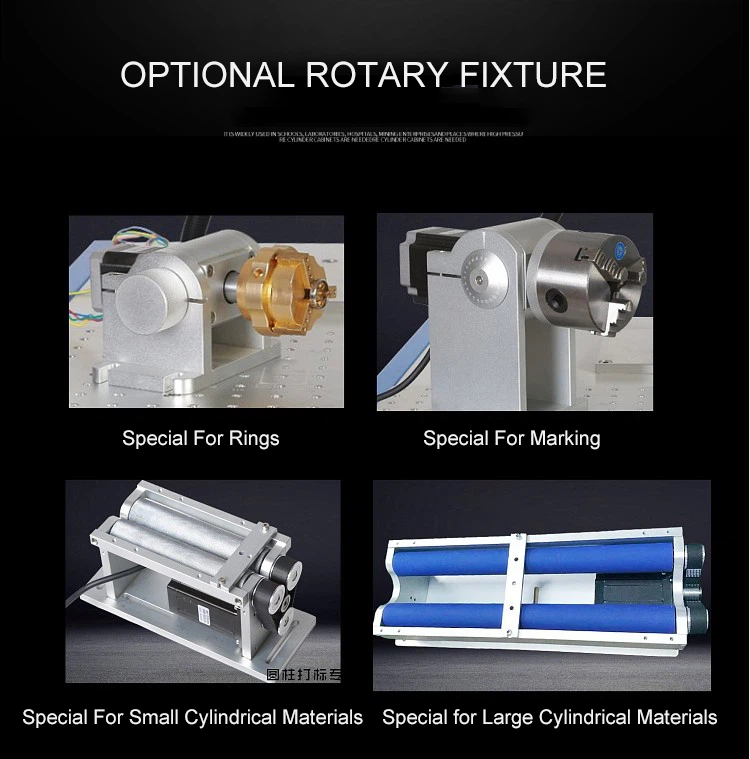

Optional parts |

Rotary Device, Lift platform, other customized Automation |

|

Color |

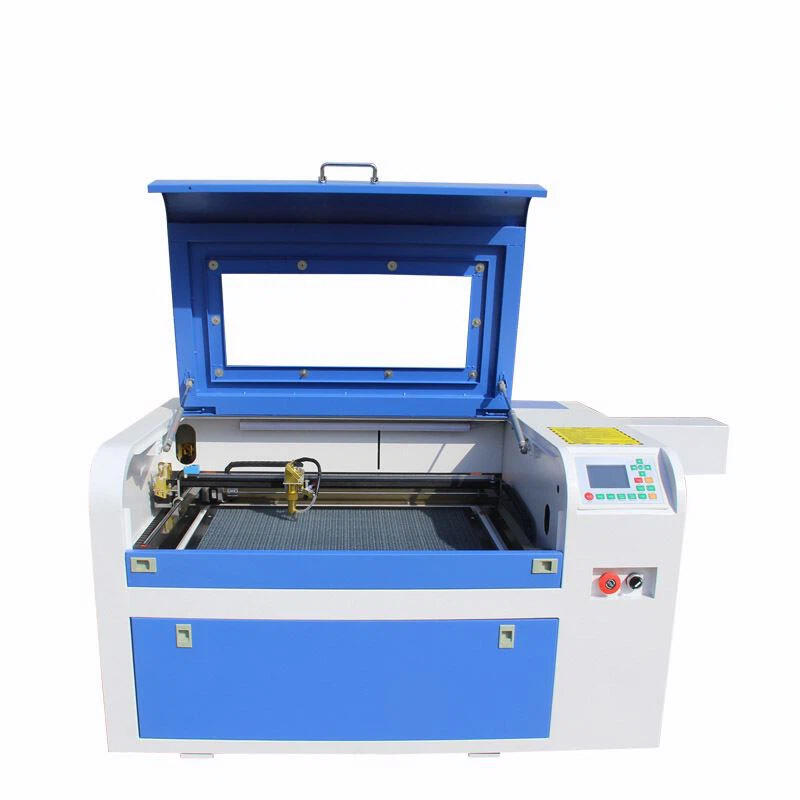

Blue and white |

|

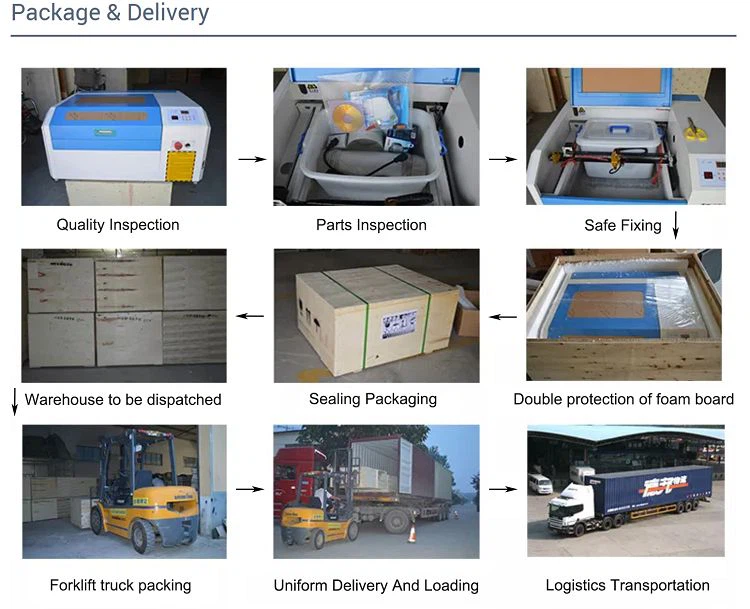

Package |

Plywood |

Details

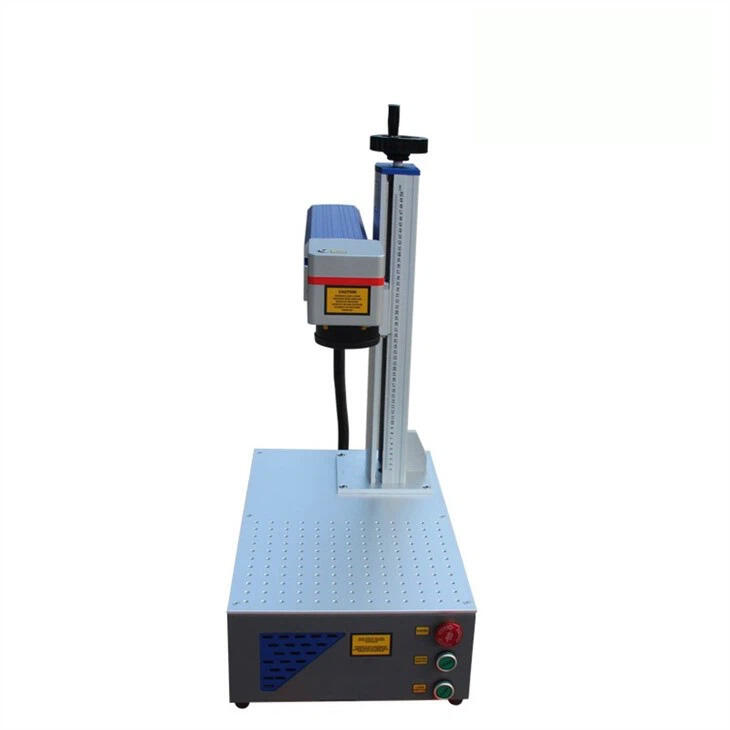

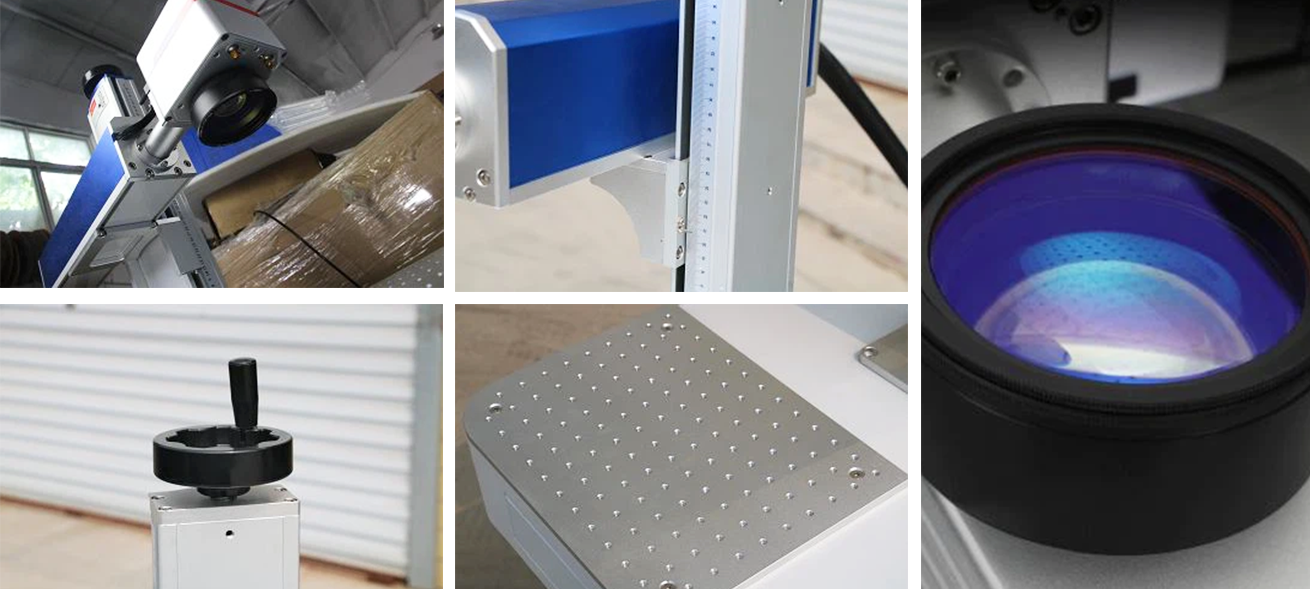

● Double red light focusing

When the two red lights overlap, it is the best focal length, which can be observed by the naked eye, which is fast and accurate.

● High Quality F-Theta Lens

Galvanometer scanning system to adopt new technology, new material, new working principle design and production.

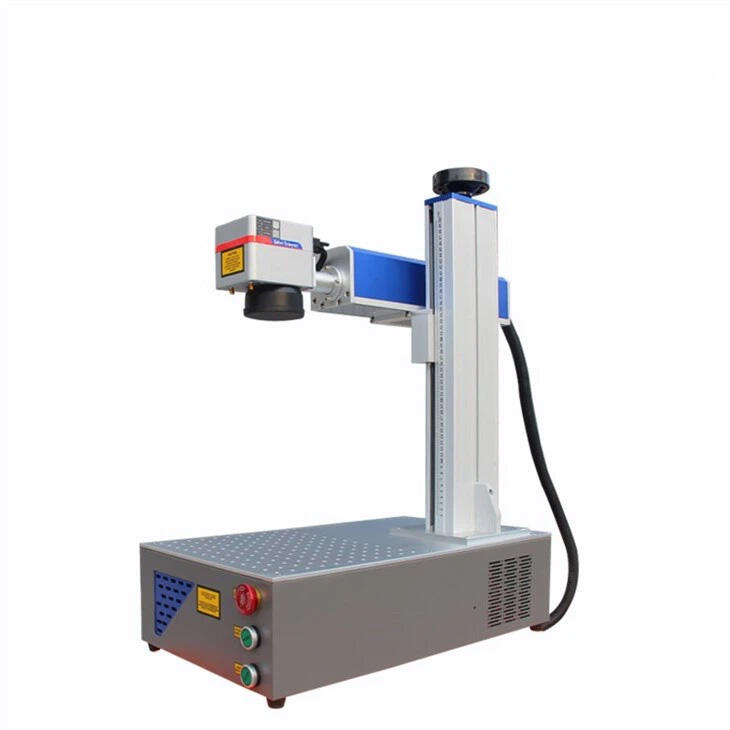

● Lifting Shaft

Can adjust the distance between the marking head and the object, marks the marking easily. The standard distance of the elevating is 500mm. It can be customized.

● Ruler Scale

Help users to adjust the height of different marking objects, so that they can locate and find it easily next time.

● Work platform

Standard positioning hole, convenient and quick positioning, head position can be adjusted arbitrarily, can realize various combinations, cooperate with software multi-station printing to improve work efficiency.

Accessories Shipped with the Machine

Optional Accessories

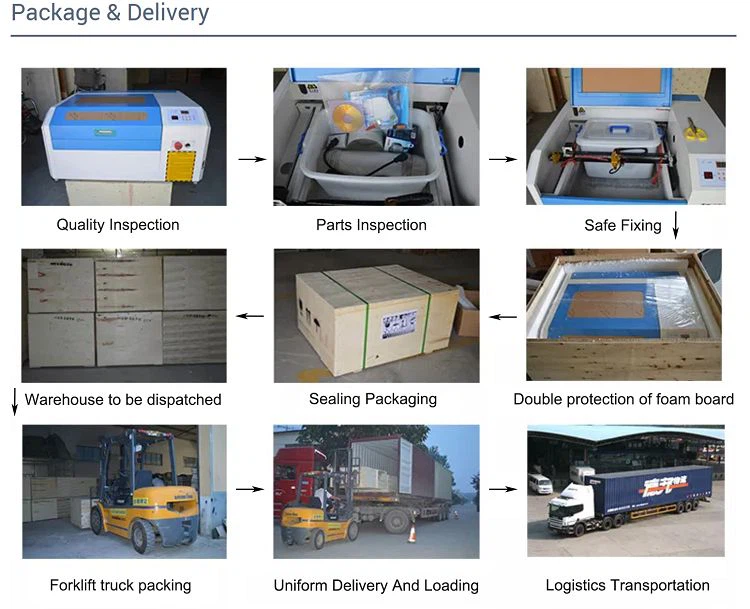

Packaging Process

Factory And Exhibition

Certifications

Hot Tags: desktop dot peen marking machine, China desktop dot peen marking machine manufacturers, suppliers, factory, RF Tube CO2 Marking Machine, Visual Positioning Automatic Laser Marking Machine, CO2 Flying Marking Machine, Laser Marking Machine, 20w fiber laser marking machine, Three Station Automatic Laser Marking System

Compositions and Package

Main Accessories

FAQ

About the Laser

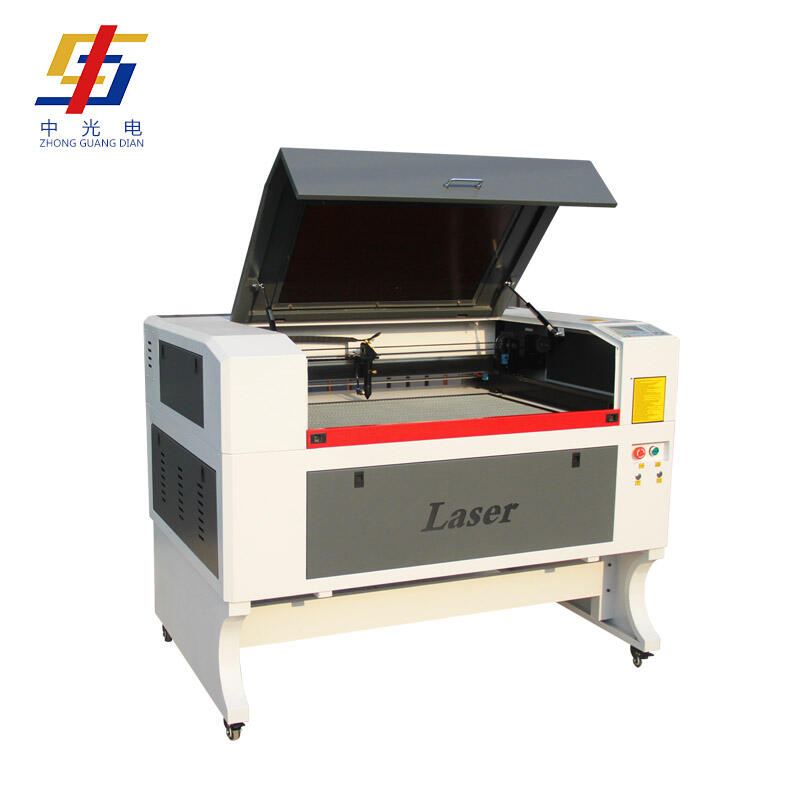

What materials can I cut or engrave with a CO2 laser?

CO2 laser machine can cut, engrave, mark a wide range of non-metal and organic materials, such as acrylics, woods, plywood, MDF, paper, cardboard, fabrics, leather, glass, stone, ceramics, and more.

What materials can I cut or engrave with a Fiber laser?

Fiber Laser can cut, engrave, mark on metals, such as steel, stainless steel, aluminum, brass, copper, silver, gold, and on some non-metal polymers, wood, fabric.

Shipping

How is the machine packaged?

Laser equipment is shipped in a wooden box with Styrofoam to protect fragile parts

How long does it take to ship by air?

After we receive the order, send the machine to one of the main DHL, FEDEX and TNT offices in China. Smaller machines are shipped by courier service. Typically, it takes 10 to 14 days.

How long does it take to ship by sea?

Larger machines are shipped by sea. Usually, it takes 6 to 10 weeks. We can help you arrange delivery directly to your location.

Customer Support

Is there a warranty?

Manufacturers extend the warranty on their devices to 18 months and replace parts at the factory purchase price.