Desktop Optical Fiber Marking Machine

◆ A desktop optical fiber marking machine is a type of laser marking system that uses a fiber laser as its source to create permanent marks or engravings on a wide range of materials. Desktop optical fiber marking machines are widely used in various industries, including manufacturing, electronics, automotive, medical, and aerospace, for product identification, traceability, branding, and decorative purposes.

- Overview

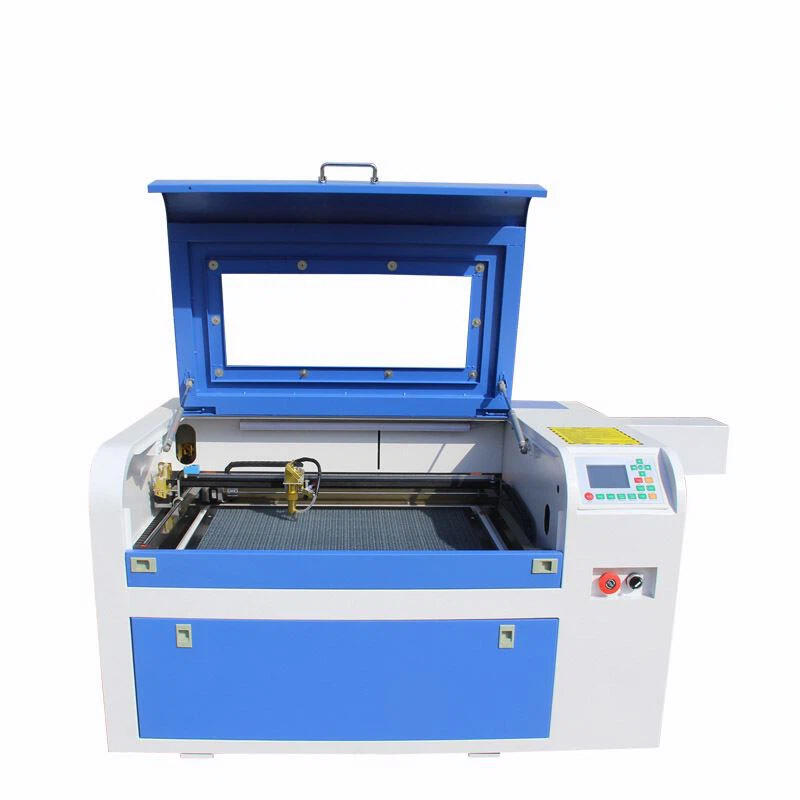

- Related Products

Hibo (Liaocheng High-tech Zone) Trading Co., Ltd

Haibo Laser is located in Liaocheng, a water city in Jiangbei known as the "Venice of North China". It is a high-tech enterprise specializing in the application of laser technology, customization, sales and service of laser equipment. We are committed to the production and research and development of laser products, and have obtained more than 20 invention patents.

Why Choose Us

● Rich Experience

Hibo Laser is a high-tech enterprise that focuses on laser technology. We specialize in customizing, selling, and servicing laser equipment. Our commitment to research and development has led to the creation of more than 20 patented inventions in the field of laser products.

● Our Products

We offer a range of products, including laser engraving, cutting, marking, and welding machines.

● Applications

Our products are widely used in various industries such as clothing and leather, trademark embroidery, advertising art, crafts, plexiglass, model manufacturing, packaging and printing, electronic appliances, hardware instruments.

● Our Services

We provide free proofing, guidance, and debugging after delivery. We also offer all necessary machine accessories, ensuring that you don't have to worry about after-sales support. We welcome you to visit our factory.

What is Desktop Optical Fiber Marking Machine

A desktop optical fiber marking machine is a type of laser marking system that uses a fiber laser as its source to create permanent marks or engravings on a wide range of materials. Desktop optical fiber marking machines are widely used in various industries, including manufacturing, electronics, automotive, medical, and aerospace, for product identification, traceability, branding, and decorative purposes.

Advantages of Desktop Optical Fiber Marking Machine

● Speed

Desktop optical fiber marking machine is mostly automated. Most of the manual tasks necessitated by other marking options are eliminated. Additionally, there is little resistance as the beam produced by fiber lasers is more concentrated and more powerful compared to other laser marking options, such as gas laser marking.

● Versatility & Flexibility

There are few limitations to what desktop optical fiber marking machine can do. It works with a wide range of materials: , plastic, metal, ceramic, polymers, silicon, gemstones, and more. Consequently, it is applied in a wide range of industries, ranging from dentistry and medical to agriculture and aerospace engineering. It also integrates well with complimentary machines and works just as well in harsh environments.

● Compact Design

Desktop optical fiber marking machines feature a more practical and compact design compared to other options. They are smaller and lighter, which makes them easily portable and ideal for use in remote settings. They are also less sensitive to impact and other elements, which also makes them more durable than other options.

● Cost Efficiency

A desktop optical fiber marking machine is easier to work with compared to other options. It has a lower heat output compared to other laser types, so there is a lower risk of damage from excess heat. And, as mentioned, it features a compact design built for durability, thus minimizing other risks of damage. Finally, these machines require less maintenance because of their superior quality.

Differences Between Desktop Optical Fiber Marking Machine and CO2 Laser Marking Machine

● Different lasers

The desktop optical fiber marking machine adopts a fiber laser while the Co2 laser marker adopts a Co2 laser. Working wavelength of a fiber marking machine is 1.064um, 10 times shorter than that of a CO2 laser marking machine. Due to this much smaller focal distance, the intensity of a fiber laser marking system is almost 100 times higher than a CO2 system with a similar power output.

● Different laser transmission method

Desktop optical fiber marking machines rely on fiber cables to transmit the laser, while CO2 laser markers uses optical system to transmit the laser. As a result, it's necessary to adjust the optical path of a CO2 laser marker, but there is no need for a desktop optical fiber marking machine .

● Different applications

Desktop optical fiber marking machine is applicable for marking and engraving most metals and partial non-metal materials. For example, steel, aluminum, copper, gold, engineering plastics, ceramics, epoxy resin, painting materials, electroplating material, etc. CO2 laser marking machine is good at engraving and marking most of non-metal materials. For instance, bamboo products, wood, acrylic, leather, glass, rubber and so forth. Other differences In terms of marking precision, fiber marking belongs to a nanoscale machining method, so its precision is higher than CO2 laser marking.

● Other differences

In terms of marking precision, fiber marking belongs to a nanoscale machining method, so its precision is higher than CO2 laser marking. The maximum service life of a desktop optical fiber marking machine can reach 100,000 hours, because it doesn't need much maintenance and consumables. However, the CO2 laser marker requires regular maintenance and replacement of vulnerable parts, so its maximum life could be 30,000 hours. With the same laser power, the fiber marker price of the two also varies.

What Kind of Material can be Marked by a Desktop Optical Fiber Marking Machine?

● Metal

They can produce high-contrast marks on metals such as stainless steel, aluminum, brass, and titanium without harming the substance of the material. Desktop optical fiber marking machines are capable of marking barcodes, QR codes, serial numbers and logos on metal surfaces important for traceability and branding purposes.

● Plastic

The making and engraving of plastic with laser technology it can be complex for the simple reason of the vast different densities, mixes, and types of plastics. However, if you are looking a machine that can mark over some specific plastic materials and engrave at the same at high speed on metal surfaces, then the desktop optical fiber marking machines is the best choice. These are some of the most common plastics fiber marking machines can engrave PLT, PS, ABS, PBT,

● Fiberglass

Marking fiber-based materials such as fiberglass should be done with the right machine. This is because using the wrong laser technique or machine can disrupt the structural integrity of the fiber, leaving a blurry mark. On the other hand, carbon fiber is easier to mark, although you might experience contrast-issue due to the material and the marking having the same color.

● Synthetic leathers

Synthetic leather is often used in making clothing accessories and automotive interiors. Because they are made of thermoplastic polymers, engraving using fiber lasers is easy. When marking synthetic polymers, it is important to use a low laser power due to the properties of the materials.

● Rubber

Black rubber is a flexible material with high tear and abrasion resistance. It comes in different types, such as natural and silicone rubber, each compatible with desktop optical fiber marking machines due to their softness and high absorption rate.

Application of Desktop Optical Fiber Marking Machine

Desktop optical fiber marking machines are used in the automotive industry to mark parts and components for traceability, identification, and branding. It is also used to create car logos, serial numbers, and barcodes.

Desktop optical fiber marking machines are used in the medical industry to mark surgical instruments, implants, and medical devices with unique identification codes. They are also used to create high-quality logos and markings on contact lenses and other medical devices.

Desktop optical fiber marking machines are used in the electronics industry to mark circuit boards, connectors, and electronic components with unique identification codes. They are also used to create high-quality labels for electronic devices and appliances.

Desktop optical fiber marking machines are used in the jewelry industry to create intricate designs on metal surfaces. They can create precise markings on gold, silver, and other metals, allowing jewelers to create custom pieces that are both unique and highly intricate.

Desktop optical fiber marking machines are used in the aerospace industry to mark parts and components for traceability and identification. They can create high-quality markings on metals, plastics, and other materials used in the construction of aircraft and spacecraft.

What to Consider When Choosing a Desktop Optical Fiber Marking Machine

● Considering the Machine Table Size

The best desktop optical fiber marking machine uses the machine table to place and hold the product. Usually, the product is first placed and gripped on the machine table, and then the engraving process can start. So, you must know the maximum product size you need to engrave. Based on this, you can filter all the available machines that can process that maximum product size. Selecting a machine like this will enable you to engrave all products within the maximum dimensions limit.

● Machine Engraving Area

The machine engraving area, also known as the machine working area, is the area limit a machine can engrave. It is different from the machine table size. The table size is the machine's ability to hold the workpiece, whereas the working area is the cross-section area engraved. The working area is always less than the table size. It depends on the laser field of view.

● Machine Material Compatibility

The first thing you need to consider is the type of material needed to engrave. There are two types of materials: non organic materials and organic materials. Organic materials are plastics, glass, paper products, and wood. You can use the desktop optical fiber marking machine for both materials.

● Laser Beam Power

The more powerful the laser is, the faster the process will be. You need to determine your type of cycle time for the operation. If you need short cycle times, higher-power machines are the best option. But if not, you can opt for low-power laser engraving machines.

● Machine Parameters

It is time to consider different machine parameters that concern your business. The desktop optical fiber marking machines use a computer system to take CAD files of patterns to be engraved. So, the selected machine should have a powerful computer system installed. In computers, dedicated software enables computers to read CAD files. They convert them into machine operational instructions. The machine software should be compatible with most CAD file formats and easy to use.

● Cost

This includes analyzing both initial purchase price and long-term operational costs. A cost-effective machine must strike a balance between upfront investment costs as well as ongoing expenses while at the same time serving your marking needs effectively.

What is the Depth of the Marking by the Desktop Optical Fiber Marking Machine?

The depth of marking by a desktop optical fiber marking machine typically ranges from 0.01 mm to 0.5 mm, depending on various factors such as the material being marked, the power of the laser, and the speed of marking. Fiber laser markers are highly precise and are primarily used for marking metals, plastics, ceramics, and other materials with shallow engravings. For deeper markings, multiple passes of the laser may be required. The marking depth can also be influenced by the focus of the laser and the material's reflectivity, making fiber lasers versatile for different industrial marking needs.

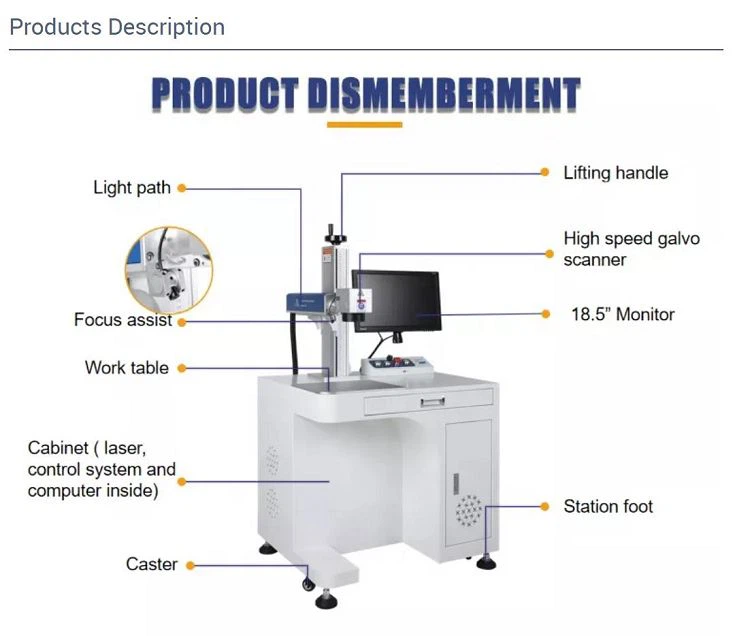

Components of Desktop Optical Fiber Marking Machine

● Work Table

The flat surface where the workpiece is placed for marking. Desktop models typically have adjustable work tables to accommodate different material sizes.

● Cabinet

The protective housing for the laser components, often equipped with a safety door to ensure safe laser operation, preventing accidental exposure.

● Galvanometer, field lens

The galvanometer and the field lens form the laser marking head. The galvanometer is the core component that controls the change of the optical path, and the field lens is an important component that controls the laser marking format.

● Industrial computer, display

The industrial computer and the display are actually our commonly used PCs. The difference is that they are connected in series with optical signals and electrical signals to control the entire software part.

● Fiber laser source

The element producing laser by the gain medium of glass fiber blended with rare earth element, therefore, it is the core of a fiber laser marking machine. Popular brands include IPG, Raycus, or MAX.

● Marking card

Marking card also called laser control card, laser marking card, generally marking with golden orange. It is used to convert the text patterns we draw in the computer into analog signals or digital signals, and then transmit them to the galvanometer.

● Keep It Clean: To have clear and precise laser paths, you must clean the lens, mirrors and other optical elements regularly; also use recommended cleaning solutions and soft cloths for scratching is avoided.

● Filters: The air filters as well as water should be checked at regular intervals so replacement can be done when necessary. Debris doesn't affect the performance of lasers due to clean filters simultaneously they help in cooling off the internal components.

● Oiling Moving Parts: Rails as well as bearings that move on this device require oiling after a period of time in order to keep them from tearing out and make them operate smoothly. Refer to manufacturers instructions for proper type of lubricant.

● Cooling Systems Have To Be Monitored: For those machines that utilize water for cooling its crucial to confirm if the water is still pure and the flow rate is adequate. Anytime there are any blockages or leaks coolant should be repaired instantly by preventing overheating.

● Software And Firmware Updates: Always keep your desktop optical fiber marking machines software up-to-date with new features and improvements. This will solve bugs that may come along with regular updates consequently improving efficiency of the machine.

FAQ

Q: What are the safety precautions for desktop optical fiber marking machine?

Q: How do you maintain a desktop optical fiber marking machine?

Q: How does a desktop optical fiber marking machine work?

Q: What are the typical applications of a desktop optical fiber marking machine?

Q: How fast can a desktop fiber marking machine operate?

Q: What software is used with desktop optical fiber marking machines?

Q: Can a desktop optical fiber marking machine be used for deep engraving?

Q: Can desktop optical fiber marking machines be integrated into automated systems?

Q: Can desktop optical fiber marking machines mark in color?

Q: How accurate is the marking from an desktop optical fiber marking machine?

Hot Tags: desktop optical fiber marking machine, China desktop optical fiber marking machine manufacturers, suppliers, factory, Handheld Laser Welding Machine, Mobile Fiber Laser Marking System, Visual Positioning Automatic Laser Marking Machine, sheet metal laser cutting machine, RF Tube CO2 Marking Machine, 150w laser spot welding machine

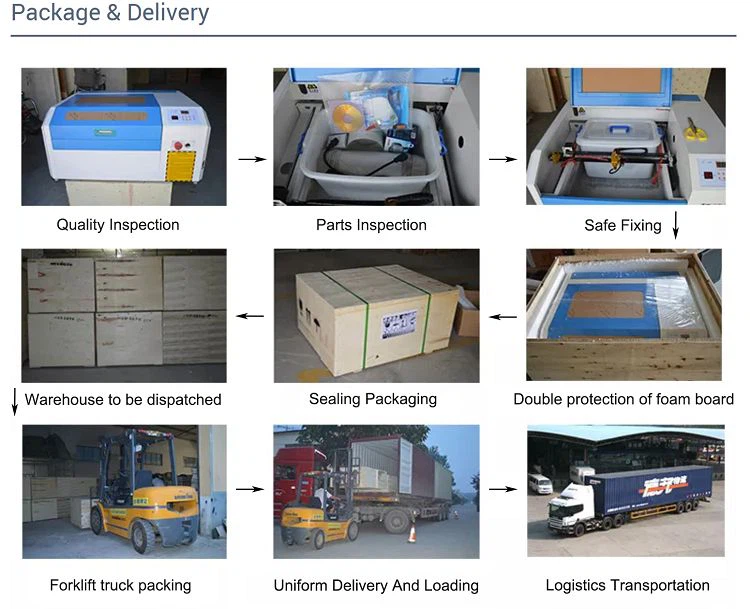

Compostions and Package