F-Theta Lens

◆ F-Theta lenses, also known as flat-field lenses or scan lenses, are specially designed lenses used in applications that require precise control of light, such as laser marking, engraving, and cutting. These lenses transform the incoming beam path into a straight line to provide a consistent beam size and intensity across the entire field, minimizing any variations and distortions typically associated with standard focusing lenses.

- Overview

- Related Products

Hibo (Liaocheng High-tech Zone) Trading Co., Ltd

Haibo Laser is located in Liaocheng, a water city in Jiangbei known as the "Venice of North China". It is a high-tech enterprise specializing in the application of laser technology, customization, sales and service of laser equipment. We are committed to the production and research and development of laser products, and have obtained more than 20 invention patents.

Why Choose Us

● Rich Experience

Hibo Laser is a high-tech enterprise that focuses on laser technology. We specialize in customizing, selling, and servicing laser equipment. Our commitment to research and development has led to the creation of more than 20 patented inventions in the field of laser products.

● Our Products

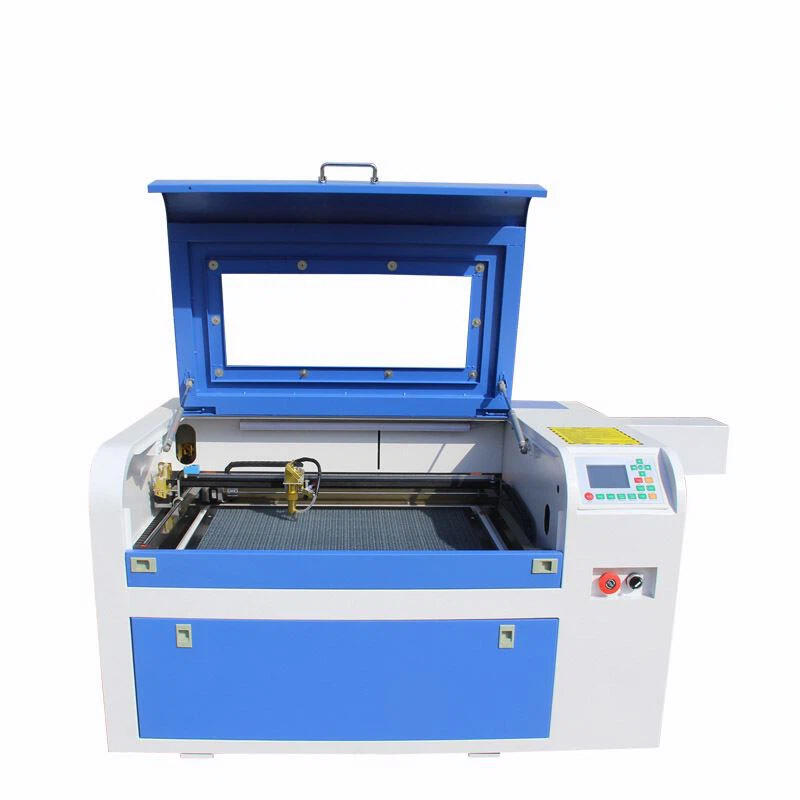

We offer a range of products, including laser engraving, cutting, marking, and welding machines.

● Applications

Our products are widely used in various industries such as clothing and leather, trademark embroidery, advertising art, crafts, plexiglass, model manufacturing, packaging and printing, electronic appliances, hardware instruments.

● Our Services

We provide free proofing, guidance, and debugging after delivery. We also offer all necessary machine accessories, ensuring that you don't have to worry about after-sales support. We welcome you to visit our factory.

What is F-Theta Lens

F-Theta lenses, also known as flat-field lenses or scan lenses, are specially designed lenses used in applications that require precise control of light, such as laser marking, engraving, and cutting. These lenses transform the incoming beam path into a straight line to provide a consistent beam size and intensity across the entire field, minimizing any variations and distortions typically associated with standard focusing lenses.

Advantages of F-Theta Lens

● Maintain a Constant Focal Length

One of the main advantages of the F-theta lens is its ability to maintain a constant focal length over a flat field. This means that no matter where the laser beam is directed within the scan area, the focal point will remain consistent, ensuring uniformity and precision in the processing of materials. This is crucial for applications that require high levels of accuracy, such as micro-machining and PCB production.

● Versatility

F-theta lens also have a large depth of focus, which allows for processing of materials with uneven surfaces or varying thicknesses. This versatility makes them suitable for a wide range of materials, including metals, plastics, ceramics, and composites. Additionally, the design of F-theta lens minimizes distortion and aberrations, resulting in clear and sharp images without any unwanted artifacts.

● Precision and Accuracy

The F-theta lens low distortion rate and high image clarity ensure that even the most intricate details are accurately captured, making it essential for high-precision tasks. Its compact size and standardized specifications, such as back focal length, facilitate seamless integration into existing optical systems, reducing downtime and enhancing productivity.

● Safety and Usability

The F-theta lens ample working distance and robust design ensure safe and efficient operation, particularly in automated systems and environments where safety is critical. The F-theta lens wide wavelength range and compact design make it highly adaptable for various industrial, medical, and scientific applications, supporting different laser types and materials.

Principle of Operation

The basic principle behind F-Theta lenses lies in their unique design and function. In a typical lens system, such as a spherical lens, the lens focuses light onto a curved surface due to its inherent curvature. The light coming in at greater angles from the optical axis is brought to focus at a shorter distance than the light traveling along or near the optical axis, thus creating a curved focal field instead of a flat plane. This inherent property of a simple lens system is known as field curvature aberration, or Petzval field curvature. However, F-Theta lenses are designed such that the focal length is a linear function of the field angle (θ), ensuring a flat or planar field. The term "F-Theta" comes from this relationship, where "F" stands for focal length and "θ" stands for the field angle. Mathematically, the relationship is as follows:

F(θ) = f * θ

Where f is the focal length of the lens at the optical axis, θ is the angle of incidence, and F(θ) is the focal length at a specific angle θ.

F-Theta Lens

● Optical Glasses Vs. Fused Silica F-Theta Lens

Short pulse lasers and ultra-short pulse lasers, but also lasers with high average power issue a exceptional challenge for lenses. Processed are strongly influenced by the characteristics of regular optical glasses. For instance thermal effects change both the beam shape and the working distance. At this point fused silica presents its crucial advantage by lower sensitivity to thermal effects in comparison to optical glasses and is therefore highly recommended for the use with the named laser sources above.

● Telecentricity F-Theta Lens

Telecentric f-theta lenses undergo special design considerations to ensure that the entrance pupil is at the front focal point of the lens system, resulting in the main rays of the focused beam being perpendicular to the focal plane at any field of view angle. This telecentricity is vital in applications where precise measurements are conducted, as it prevents variations in magnification when objects move in and out of the field of view.

Why F-Theta Lens are Important in Laser Applications?

● Uniform Focus

In laser systems, maintaining a consistent focus across the entire scanning area is vital for accurate and precise results. F-theta lenses are designed specifically to provide a flat field of focus, ensuring that the laser beam remains uniform throughout the scanning process.

● Speed and Efficiency

F-theta lenses enable rapid scanning speeds without sacrificing accuracy. Their design allows for fast beam deflection while maintaining precise focus, making them ideal for high-speed laser processing applications such as marking, engraving, and cutting.

● Aberration Correction

These lenses are optimized to minimize optical aberrations such as distortion and spherical aberration, which can otherwise degrade the quality of the laser beam. This correction capability is essential for achieving high-resolution and distortion-free laser imaging.

● Compatibility with Scanning Systems

F-theta lenses are specifically engineered to work seamlessly with laser scanning systems. They are designed to compensate for the angular dependence of the scanning beam, ensuring that the laser remains focused even as it moves across the scanning area.

Application of F-Theta Lens

● Laser Marking

One of the most common applications of F-theta lens is laser marking. By using a focused laser beam to remove material or change its color, manufacturers can create permanent marks on a variety of products, such as electronic components, medical devices, and automotive parts. F-theta lenses ensure that these marks are precise and consistent, even on curved or irregular surfaces.

● Laser Engraving

F-theta lens are also widely used in laser engraving, which involves removing material to create intricate designs or patterns. This process is commonly used in the production of signage, jewelry, and promotional items. The flat field of focus provided by F-theta lenses allows for detailed engraving with minimal distortion or blurring, resulting in high-quality finished products.

● Laser Cutting

Another important application of F-theta lens is laser cutting, where a focused laser beam is used to precisely cut through materials such as metal, acrylic, and leather. F-theta lenses ensure that the laser beam remains sharp and accurate throughout the cutting process, resulting in clean and precise cuts with minimal heat-affected zones.

● 3D Printing

The f-theta lens is used in 3D printing applications to selectively solidify layers of photopolymer resin or other materials, allowing for the creation of intricate and detailed 3D objects. This lens is essential for achieving precise and uniform curing of the printing material, ensuring high-quality and accurately printed objects.

● PCB Fabrication

The f-theta lens is essential for maintaining consistent hole size and shape across the entire PCB, ensuring reliable connections and optimal performance of electronic components. This lens is particularly useful for drilling small vias and microvias in modern PCB designs, where precision and accuracy are critical.

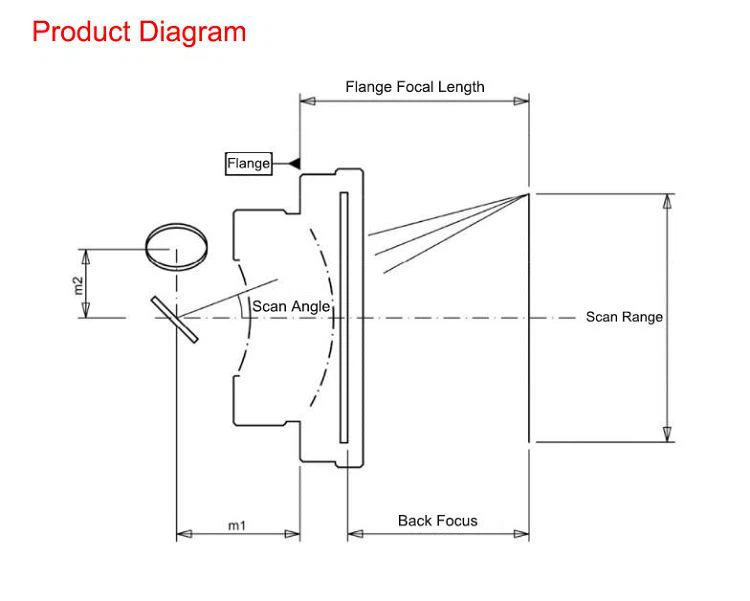

Key Parameters of a F-Theta Lens and Scanning System

When designing an F-theta lens for your application, key parameters to keep in mind are operating wavelength, spot size, and scan field diameter (SFD). The operating wavelength is the wavelength of the laser that you'll be working with. Spot size refers to the width of the laser beam. The scan field diameter SFD or scan length of an F-theta lens is defined as the diagonal length of the square in which the beam can be focused by the lens.

Another important feature of a scanning system is the output scan angle or OSA. This is the angle between the normal of the image plane and the output laser beam (the beam after it has passed through the scan lens). For a telecentric lens, the OSA will always be zero; otherwise, it will vary slightly across the image field.

Other essential parameters include working distance, which refers to the distance between the lens housing and the paraxial focus point, and field curvature, which is the deviation from a flat image plane. Even though F-theta lenses are designed to reduce field curvature, some distortion and curvature will still exist. For example, placing the zero-curvature point at the midrange of the scan can help minimize the impact. Additionally, diffraction limited performance may be a critical consideration, ensuring minimal loss of beam quality. By focusing on these elements, you can optimize your F-theta lens for precision and accuracy in your system.

What to Consider When Choosing The F-Theta Lens

The choice of lens material is pivotal in achieving the desired optical properties. Fused silica and ZnSe are common materials for f-theta lenses. Fused silica offers excellent transmission in the UV range and is suitable for applications like semiconductor processing. ZnSe, on the other hand, is advantageous for mid-infrared applications. Understanding the wavelength range of your laser system is crucial, ensuring the selected material provides optimal performance.

Coatings play a crucial role in enhancing transmission efficiency and reducing reflections. Anti-reflective coatings tailored to the laser wavelength improve overall system performance. Additionally, protective coatings can enhance durability, safeguarding the lens against environmental factors and contaminants. Assess the coatings offered by manufacturers to align them with the specific demands of your application.

Consider the laser system specifications, such as beam diameter and power levels, to ensure compatibility with the f-theta lens. The lens should be capable of handling the power density and beam characteristics of your laser source. Check if the lens is designed for continuous-wave (CW) or pulsed laser applications, as different requirements may dictate distinct lens designs.

The focal length of the f-theta lens determines the size of the focused spot on the target. Assess the working distance and spot size requirements for your application. It's essential to strike a balance between the desired spot size and working distance to achieve optimal results.

Consider the required field size for your application. Different f-theta lenses may offer varying field sizes, and selecting the appropriate lens ensures that your laser beam covers the entire scanning area without distortion.

The wavelength of the f theta lens is determined by the laser marking system. The fiber laser wavelength is 1064nm, CO2 laser wavelength is 10.6μm, green laser wavelength is 532nm, and ultraviolet laser wavelength is 355nm. We need to select the corresponding field mirror for the corresponding laser.

How to Replace the F-Theta Lens and What Settings to do After Replacement?

To replace the F-theta lens on a fiber laser marking machine, you will need to follow these steps:

Turn off the laser and unplug it from the power source. This is an important safety precaution to avoid the risk of electric shock. Remove the old lens from the laser head. This may require the use of special tools or equipment, depending on the specific model of your laser. Consult the manufacturer's instructions or a qualified technician for assistance if you are not familiar with the process.

Install the new lens in the laser head, making sure it is securely seated and aligned correctly. Turn on the laser and check the focus. Adjust the focus as needed to ensure that the laser beam is properly focused and producing the desired mark quality.

After replacing the F-theta lens, you may also need to adjust other settings on the laser to ensure optimal performance. These may include:

1. Laser power: The laser power may need to be adjusted to compensate for any differences in the transmission or focus characteristics of the new lens.

2. Wavelength: If the new lens is designed for a different wavelength range, you may need to adjust the wavelength setting on the laser to match.

3. Numerical aperture (NA): The NA value of the new lens may be different from the old lens, which can affect the focus spot size and depth of field. You may need to adjust the focus and other settings to compensate for these differences.

4. Coating: The coating of the new lens may have different transmission or reflection characteristics, which can affect the performance of the laser. You may need to adjust the settings to ensure optimal performance.

How to Clean an F-Theta Lens

Turn off the laser and unplug it from the power source. This is an important safety precaution to avoid the risk of electric shock. Remove the lens from the laser head. This may require the use of special tools or equipment, depending on the specific model of your laser. Consult the manufacturer's instructions or a qualified technician for assistance if you are not familiar with the process.

Use a f-theta lens cleaning solution specifically designed for use with optical instruments. These solutions are typically formulated to remove dirt, dust, and other contaminants without damaging the lens. Apply a small amount of cleaning solution to a soft, lint-free cloth and gently wipe the lens in a circular motion.

Rinse the lens with distilled water to remove any remaining cleaning solution. Distilled water is preferred because it is free of impurities that could potentially leave streaks or residue on the lens. Dry the f-theta lens with a clean, lint-free cloth. Be sure to remove all water droplets from the surface of the lens to prevent the formation of water spots.

It is important to handle the f-theta lens carefully to avoid scratching or damaging it. Do not use harsh cleaning agents or abrasive materials, as these can cause permanent damage to the lens. If the f-theta lens is particularly dirty or has been damaged, it may need to be replaced.

FAQ

Q: What does F-theta lens do?

Q: What is the difference between F-theta and F tan theta lens?

Q: How to clean an F-theta lens?

Q: What material is used in F-theta lens?

Q: How does the F-theta lens work?

Q: What are the common focal lengths for F-theta lens?

Q: How does an F-theta lens compare to a standard focusing lens?

Q: What is the role of the coating on an F-theta lens?

Q: Can F-theta lensbe used for 3D scanning?

Q: What is the difference between an F-theta lens and a telecentric lens?

Q: What wavelengths are F-theta lenscompatible with?

Q: What is the scan area of an F-theta lens?

Q: How does focal length affect F-theta lens performance?

Q: How do you choose the right F-theta lens for a laser system?

Q: What is the typical lifespan of an F-theta lens?

Q: Can F-theta lenses be used with different types of lasers?

Hot Tags: f-theta lens, China f-theta lens manufacturers, suppliers, factory, handheld fiber laser welding machine, Double sided Fiber Laser Marking Machine, Optical Fiber Laser, Laser Engraving Machine Motherboard, Desktop Laser Cutting Machine, Paper Laser Cutting Machine

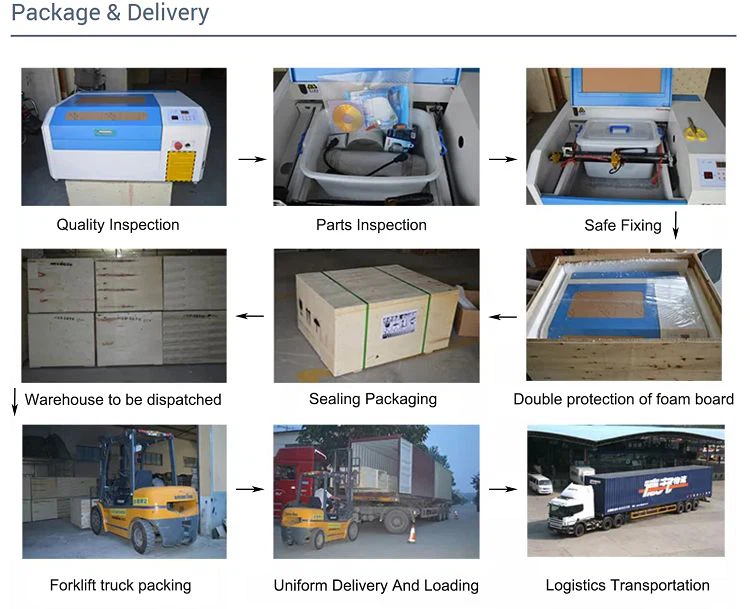

Compostions and Package