Laser Engraving Stainless Steel Marking Machine

◆ Laser Engraving Stainless Steel Marking Machine;

◆ Model: HB Optical Fiber Marking Machine-3;

◆ Laser type: Fiber laser;

◆ Laser power: 20W/30W/50W/100W;

◆ Marking speed: 7000mm/s;

◆ Working area: 100X100/150X150/200X200/300X300(mm).

- Overview

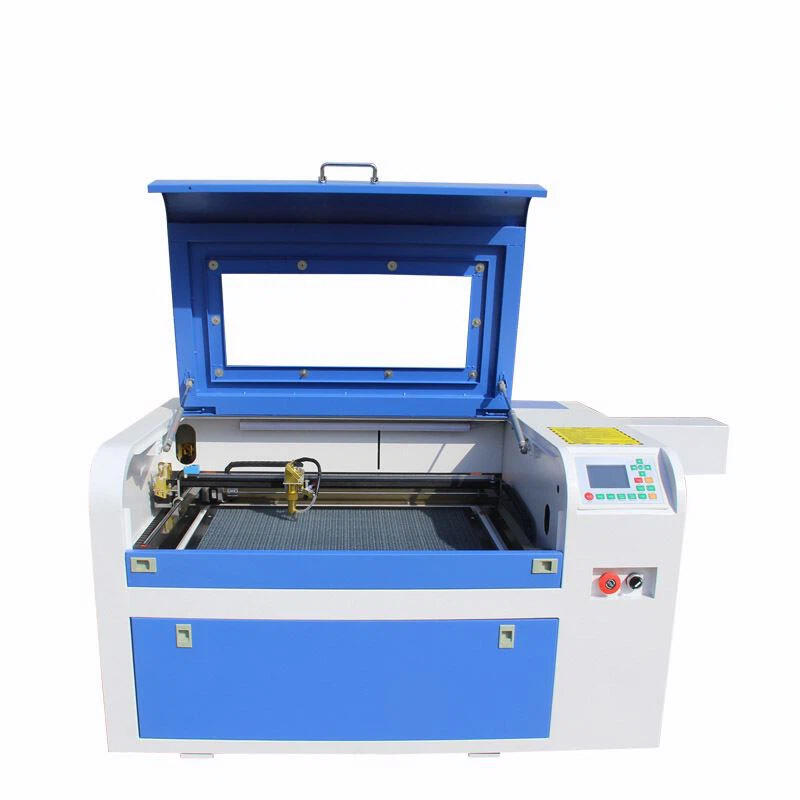

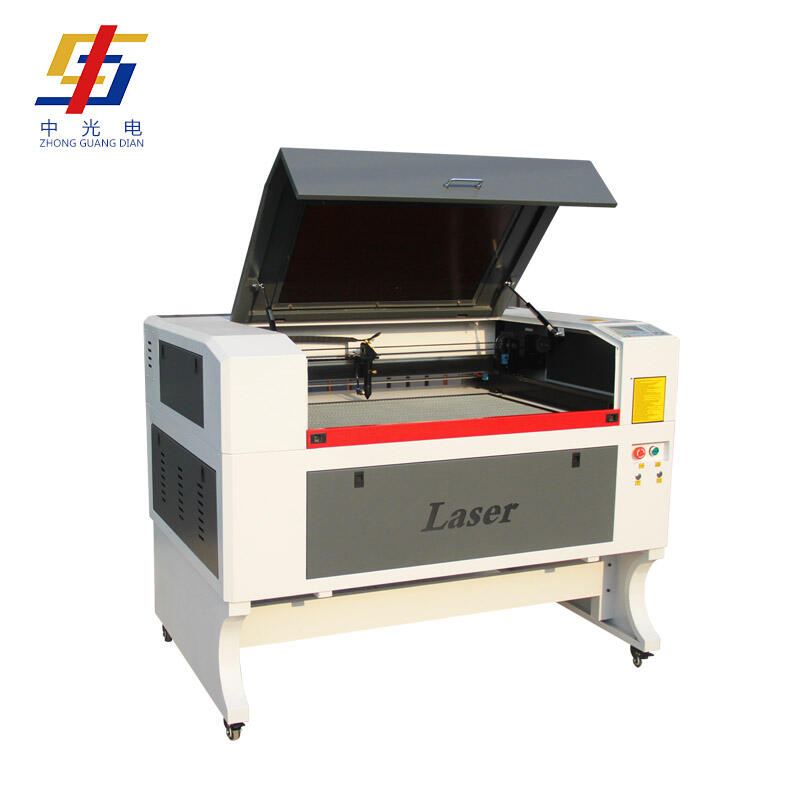

- Related Products

Introduction

The laser engraving stainless steel marking machine is specialized equipment that employs a focused laser beam to produce precise, permanent markings on stainless steel surfaces. Featuring patented double-layer enclosed dustproof technology, it requires no maintenance. This machine is commonly used for branding, serialization, and product identification, offering exceptional durability and resistance to wear.

Feature

● Advanced Three-Axis Dynamic Technology

The laser engraving stainless steel marking machine utilizes imported three-axis dynamic technology, which significantly enhances its operational efficiency. This technology provides a larger working range, making it easier to mark on extensive stainless steel surfaces. Moreover, the machine produces a finer spot diameter, ensuring precision in engraving that results in sharper, more detailed markings. This capability is especially advantageous for intricate designs and logos, delivering high-quality outcomes that adhere to industrial standards.

● Simplified Operation

A key benefit of our laser engraving machine is its user-friendly design. In contrast to traditional marking systems that often require complicated setups with manual adjustments for focus and alignment, our machine simplifies the process. As a result, operators can easily configure the system and begin marking with minimal training or technical knowledge, leading to increased productivity and reduced downtime.

● Flexible Operator Interface

Our laser engraving machine features an intuitive operator interface that enhances usability. This interface allows for flexible operation, enabling users to quickly adjust settings according to the specific material and design requirements. Such adaptability accommodates a wide range of marking tasks, from basic text to intricate graphics, making the machine suitable for various applications across industries like manufacturing, automotive, and aerospace.

● Efficiency in Processing

The design and technology of our laser engraving stainless steel marking machine foster efficient and flexible processing. The integration of advanced features allows for rapid engraving speeds without sacrificing quality, significantly boosting overall operational efficiency. This capability is vital for businesses aiming to fulfill high-volume production demands while maintaining consistent quality.

● Durability and Longevity

Laser marking machines are recognized for their robustness and longevity, especially when working with durable materials such as stainless steel. The reduced wear and tear associated with laser engraving, compared to traditional methods, leads to lower maintenance costs and an extended lifespan for the machine. This aspect offers an excellent return on investment, making it an ideal choice for businesses committed to sustainability.

● Environmentally Friendly

Laser engraving processes generate minimal waste relative to other marking techniques. With no inks or solvents involved, the process is environmentally friendly, aligning with contemporary industrial practices that emphasize sustainability. This feature not only aids businesses in complying with regulatory requirements but also resonates with environmentally conscious consumers.

Applications

● Industrial Equipment Labeling

In industrial environments, marking equipment with serial numbers, barcodes, and identification codes is essential for traceability and inventory management. Laser engraving produces high-quality, durable markings capable of withstanding harsh conditions. For instance, manufacturing companies frequently engrave their equipment to optimize supply chains, allowing for quick access to parts information and history, which ultimately boosts operational efficiency.

● Consumer Product Personalization

The growing demand for personalized products has led to an increase in custom engraving on stainless steel items, including kitchenware, watches, and jewelry. Laser marking machines can engrave logos, names, or unique designs, enabling businesses to provide personalized gifts that resonate with consumers. For example, companies that produce customized stainless steel water bottles can engrave individual names or special messages, enhancing brand identity and offering a distinctive product that differentiates itself in the marketplace.

● Medical Device Marking

In the medical field, adhering to strict regulations is critical. Laser engraving stainless steel marking machines create permanent, corrosion-resistant markings on surgical instruments and medical implants, ensuring traceability and compliance with industry standards. For example, hospitals frequently engrave surgical tools with identification numbers to monitor usage and maintain compliance with health regulations, which is vital for patient safety.

● Automotive Parts Identification

The automotive sector relies heavily on accurate part identification for quality control and traceability. Engraving part numbers, dates, and other critical information on automotive components allows manufacturers to effectively monitor production processes. For instance, a car manufacturer might employ laser engraving to mark engine parts, ensuring that each component can be tracked throughout the supply chain, thereby enhancing product quality and safety.

● Aerospace Component Marking

Aerospace manufacturers are subject to stringent traceability and identification requirements. Laser engraving stainless steel marking machines are employed to mark aerospace components with precise and durable identification marks, including serial numbers and QR codes. For example, an aerospace company may engrave vital aircraft components to comply with regulatory standards, ensuring that each part can be traced back through its manufacturing history, which is crucial for safety and compliance in aviation.

Technical Parameters

| Laser Type | Fiber Laser |

| Working Area | 100X100/150X150/200X200/300X300(mm) |

| Laser Power | 20W/30W/50W/100W |

| Laser Wavelength | 1064nm |

| Beam Quality | m²<1.5 |

| Application | metal and partial nonmetal |

| Marking Speed | ≤7000mm/s |

| Repeated Precision | ±0.02mm |

| Power supply | 1 Ph 220V±10%;50/60Hz |

| Cooling Mode | Air Cooling |

| Supported Graphic Formats | AI,BMP,DST,DWG,DXF,DXP,LAS,PLT |

| Controlling Software | EZCAD |

| Working Temperature | 15℃-45℃ |

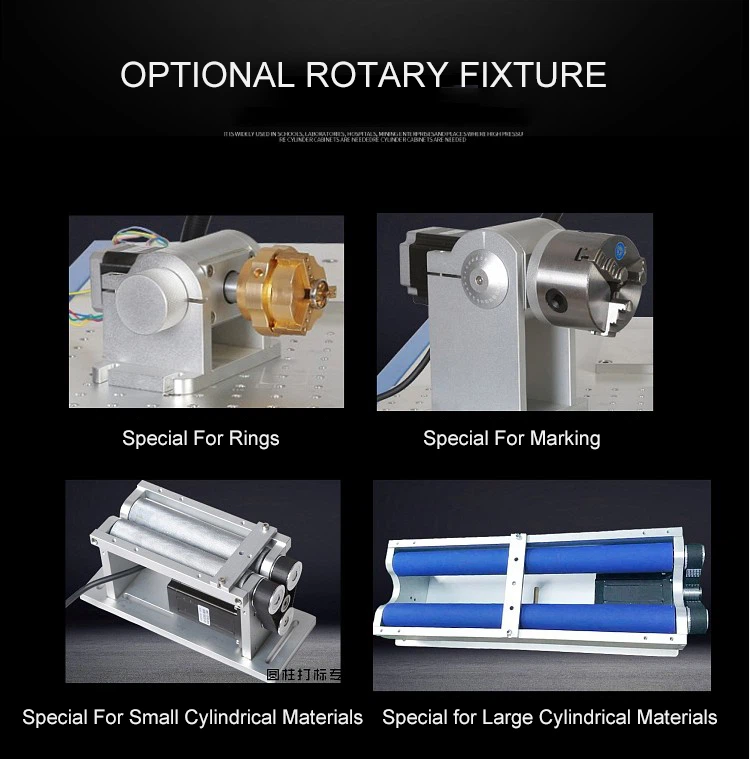

| Optional Parts | Rotary Device,Lift Platform,Other Customized Automation |

| Warranty | 1 Year |

| Gross Weight | 90KG |

Details

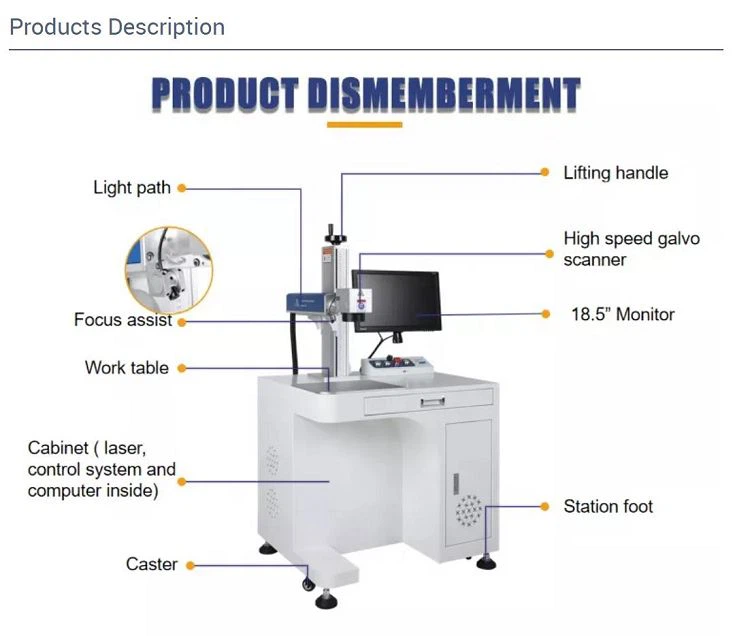

● Field Lens

Same power for example 20W if working area smaller,the marking depth by one time is bigger

● Lifting Handle

High quality and stable, adjust the up and down for different height material marking

● Ruler

High precision ruler accurate view of fixed size more precise and detailed.

● Laser device/Source

optional:MAX /IPG /Raycus / laser source

● Rotary System

Complex rotary for irregular shape, but can only hold 60mm and 80mm need to buy

● Control Switch

Humanized control system, easy to operate, safe and convenient, dust proof desig

Accessories Shipped with the Machine

Optional Accessories

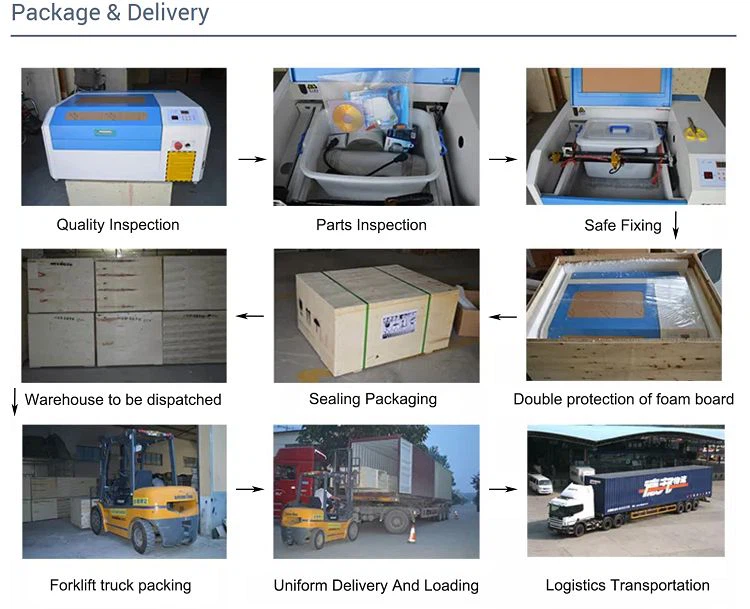

Packaging Process

Factory And Exhibition

Certifications

Hot Tags: laser engraving stainless steel marking machine, China laser engraving stainless steel marking machine manufacturers, suppliers, factory, Split Optical Fiber Marking Machine, Glass Tube CO2 Marking Machine, Visual Positioning Automatic Laser Marking Machine, UV Laser Engraving Machine, 3D CO2 Laser Marking, Three Station Automatic Laser Marking System

Compositions and Package

Main Accessories

FAQ

About the Laser

What materials can I cut or engrave with a CO2 laser?

CO2 laser machine can cut, engrave, mark a wide range of non-metal and organic materials, such as acrylics, woods, plywood, MDF, paper, cardboard, fabrics, leather, glass, stone, ceramics, and more.

What materials can I cut or engrave with a Fiber laser?

Fiber Laser can cut, engrave, mark on metals, such as steel, stainless steel, aluminum, brass, copper, silver, gold, and on some non-metal polymers, wood, fabric.

Shipping

How is the machine packaged?

Laser equipment is shipped in a wooden box with Styrofoam to protect fragile parts

How long does it take to ship by air?

After we receive the order, send the machine to one of the main DHL, FEDEX and TNT offices in China. Smaller machines are shipped by courier service. Typically, it takes 10 to 14 days.

How long does it take to ship by sea?

Larger machines are shipped by sea. Usually, it takes 6 to 10 weeks. We can help you arrange delivery directly to your location.

Customer Support

Is there a warranty?

Manufacturers extend the warranty on their devices to 18 months and replace parts at the factory purchase price.