Laser Rust Removal Machine

◆ Laser Rust Removal Machine;

◆ Model: HB-HJ 1000/1500/2000;

◆ Laser power: 1000W/1500W/2000W;

◆ Welding speed:0-120mm/s;

◆ Working voltage: (220V or 380V) ±10% 50HZ/60HZ.

- Overview

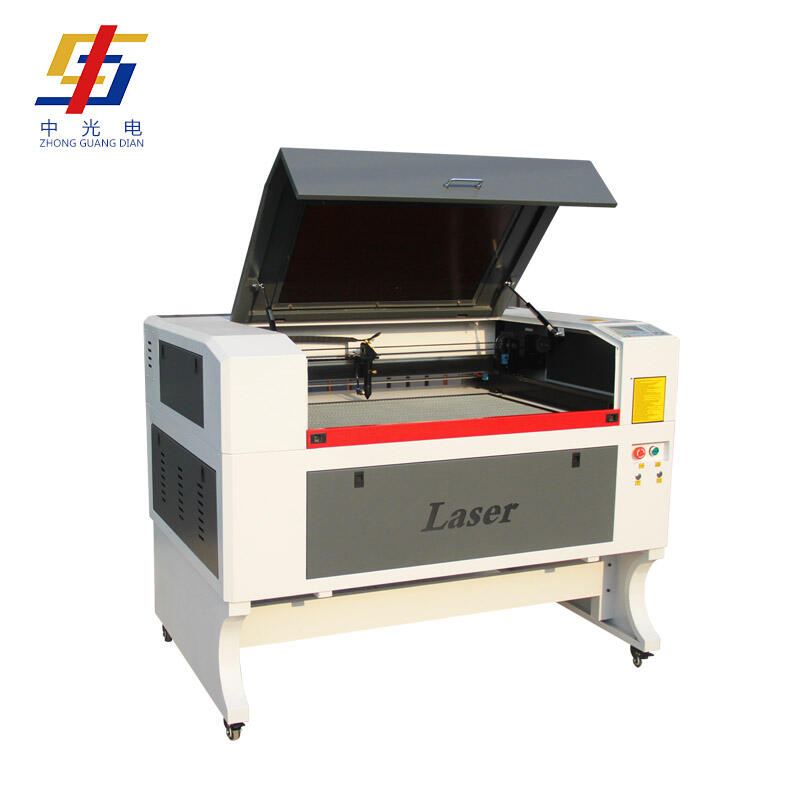

- Related Products

Application Materials

carbon steel,stainless steel, galvanized sheet, electrolytic sheet, silicon steel, road alloy, brass, copper, aluminum, etc.

Technical Parameters

| Model | HB-HJ1000/1500/2000 |

| Laser Power | 1000W/1500W/2000W |

| Fiber Length | 10 meter (standard),15 meter (optional) |

| Working Way | Continuous/Modulated Pulse |

| Welding Speed | 0mm-120mm/S |

| Chiller | Dual temperature and control chiller |

| Applicable plate thickness | 0-10mm |

| Gap Requirements | 0mm-2mm |

| Voltage | AC220V±10% 50HZ/AC380V±10% 50HZ |

| Item Weight | About 240kg |

Advantages of Laser Cleaning

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid-solid strong impact cleaning, and high-frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1. Environmental advantages:

Laser cleaning is a "green" cleaning method. It does not require the use of any chemicals or cleaning solutions. The waste after cleaning is solid powder. It is small, easy to store, and recyclable. Easily solve environmental pollution problems caused by chemical cleaning.

2. Effect advantage:

The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the object to be cleaned, damages the surface of the object to be cleaned or the cleaning medium adheres to the surface of the object to be cleaned, which cannot be removed and causes secondary pollution. The non-abrasive and non-contact laser cleaning can solve these problems; laser cleaning can remove all kinds of pollutants on the surface of various materials, and achieve the cleanliness that cannot be achieved by conventional cleaning. It can also selectively clean the surface of the material from contamination without damaging it.

3. Advantages of control:

The laser can be transmitted through optical fiber, and cooperate with manipulators and robots to facilitate long-distance operations. It can clean parts that are difficult to reach by traditional methods and ensure the safety of personnel in some dangerous places.

4. Cost advantage:

Laser cleaning has high efficiency and saves time; although the investment in the one-time purchase of a laser cleaning system in the early stage is high, the cleaning system can be used stably for a long time and the operating cost is low. What's more, it can be easily automated.

Details

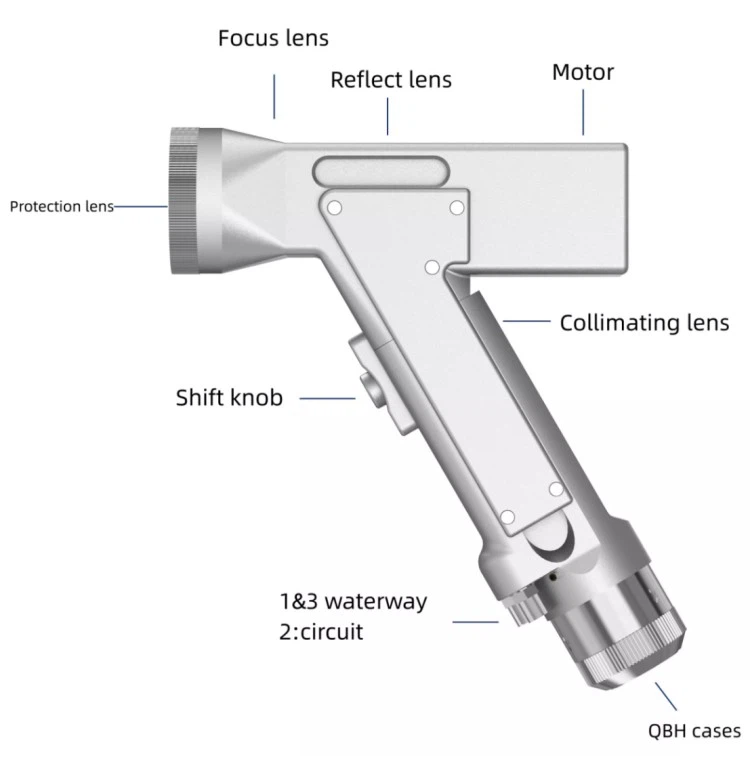

● Cleaning Head

The laser rust removal machine uses famous brand cleaning head. It's easy for operation. The weight is only 0.8kg at the most.

● Laser Source

Top brand fiber laser source Raycus has high power. The energy density is high, the heat input is low, and the amount of thermal deformation is small.

● The Automatic Wire Feed is Optional.

The wire feeder can be chosen. it's small in size, flexible in processing, low in operation and maintenance costs, and convenient for welding.

● Water Chiller

It has a high-power water chiller which can ensure the machine won't overheat if it works for a long time.

● Long Distance Work

The optical fiber cable in the rust removal machine is 10M. 15M is also available if needed.

Hot Tags: laser rust removal machine, China laser rust removal machine manufacturers, suppliers, factory, Fiber Optical Laser Scanning Welding Machine, stainless hose fittings laser welding machine, laser welding machine for automobile industry, Automatic Loading and Unloading Laser Welding Machine, laser welding machine for hardware, german jewelry laser welding machine

Compositions and Package

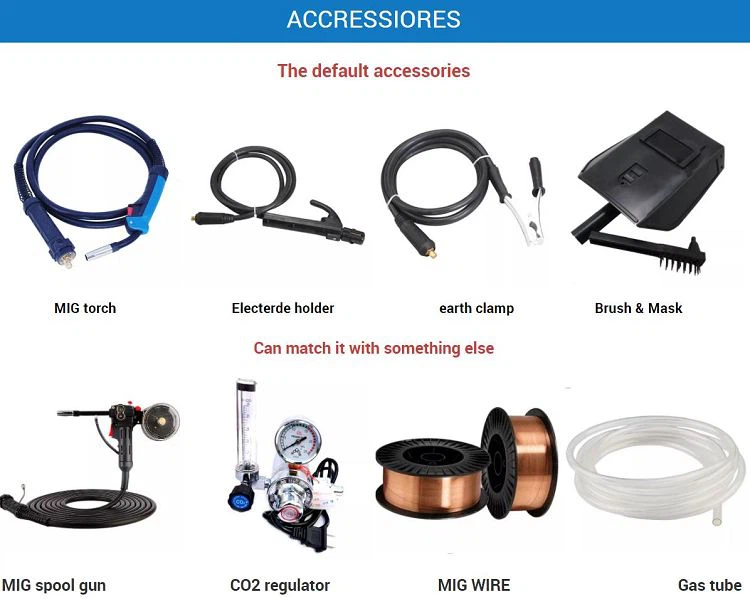

Main Accessories

FAQ

● About the Laser

What materials can I cut or engrave with a CO2 laser?

CO2 laser machine can cut, engrave, mark a wide range of non-metal and organic materials, such as acrylics, woods, plywood, MDF, paper, cardboard, fabrics, leather, glass, stone, ceramics, and more.

What materials can I cut or engrave with a Fiber laser?

Fiber Laser can cut, engrave, mark on metals, such as steel, stainless steel, aluminum, brass, copper, silver, gold, and on some non-metal polymers, wood, fabric.

● Shipping

How is the machine packaged?

Laser equipment is shipped in a wooden box with Styrofoam to protect fragile parts

How long does it take to ship by air?

After we receive the order, send the machine to one of the main DHL, FEDEX and TNT offices in China. Smaller machines are shipped by courier service. Typically, it takes 10 to 14 days.

How long does it take to ship by sea?

Larger machines are shipped by sea. Usually, it takes 6 to 10 weeks. We can help you arrange delivery directly to your location.

● Customer Support

Is there a warranty?

Manufacturers extend the warranty on their devices to 18 months and replace parts at the factory purchase price.