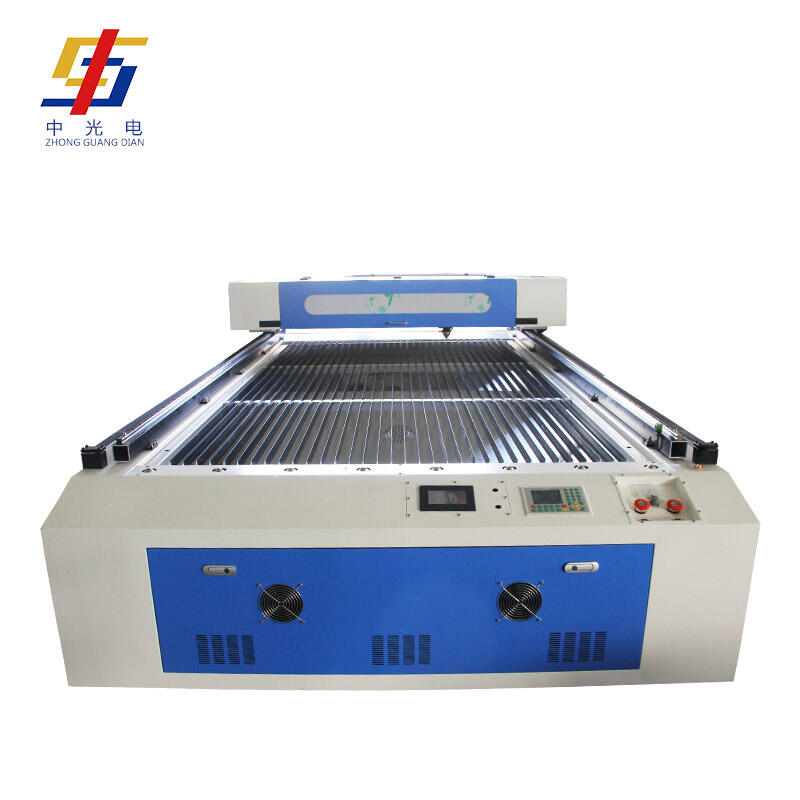

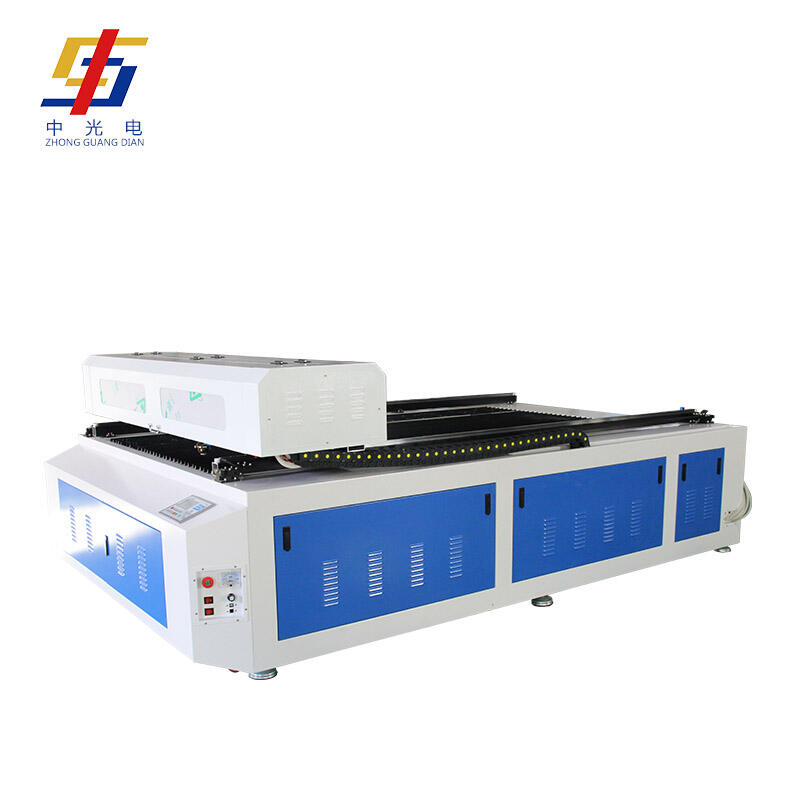

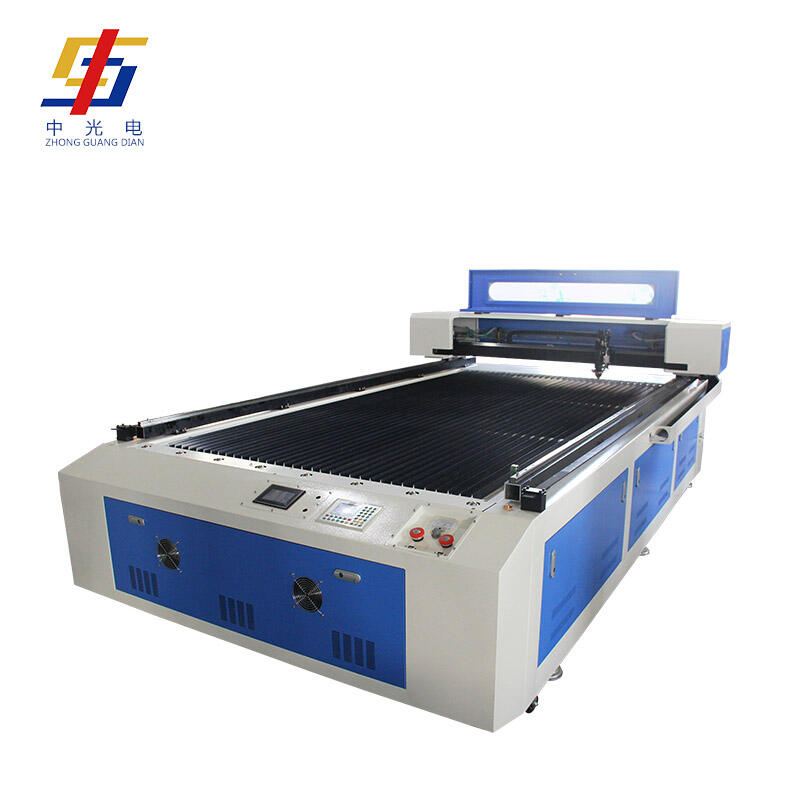

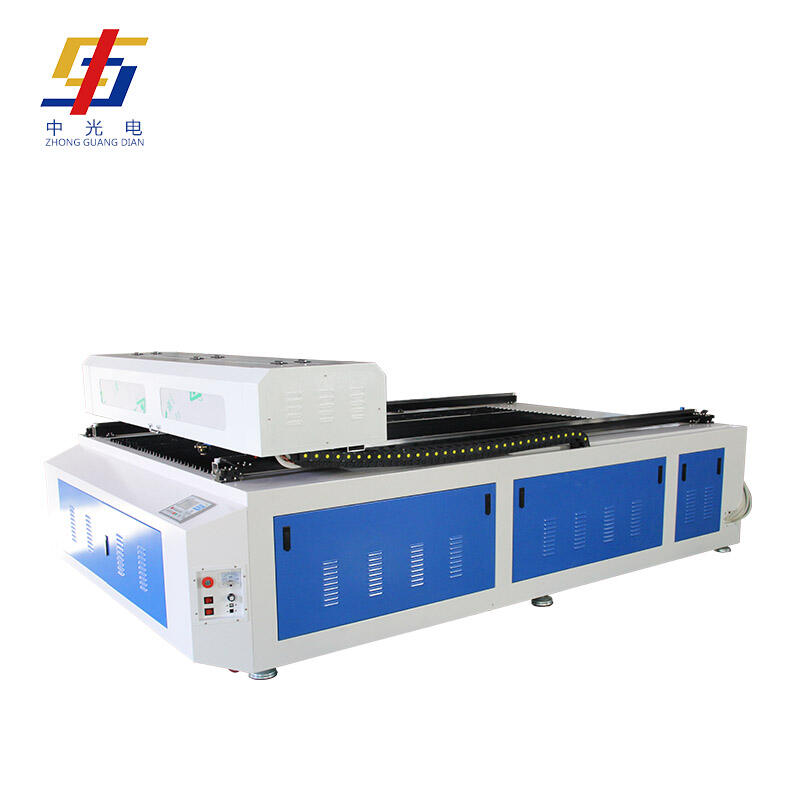

Metal And Non-metal Laser Cutting Machines

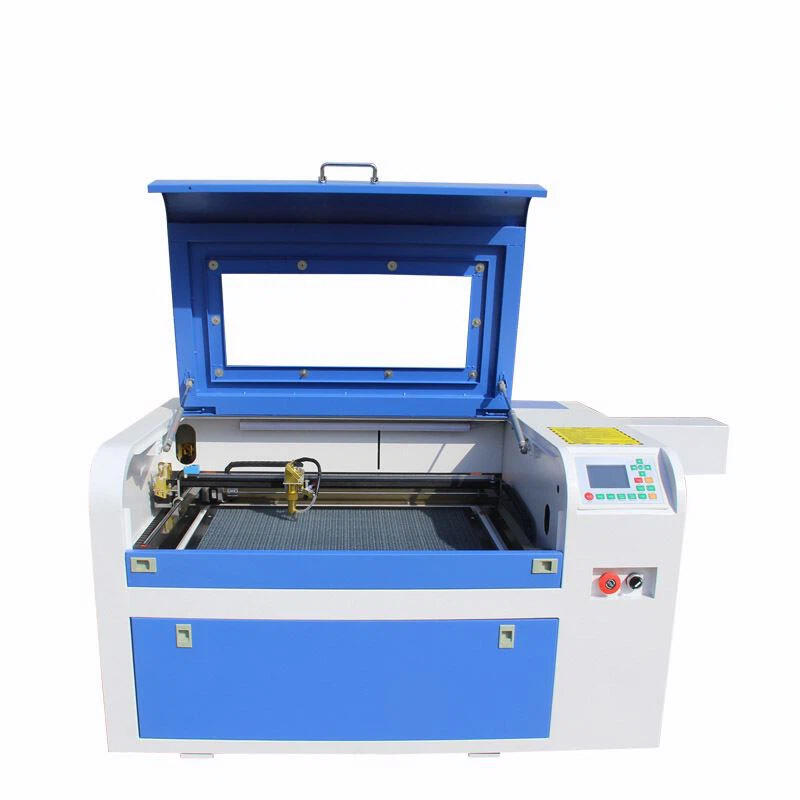

◆ Laser Mixed Cutting Machine;

◆ Model: HB-H1325;

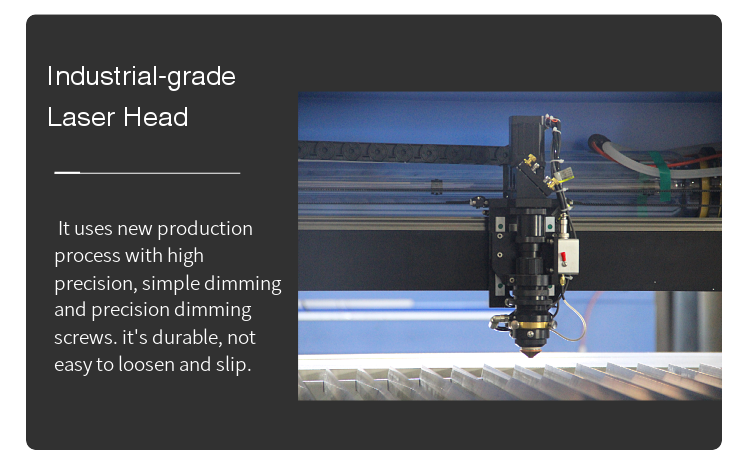

◆ Laser Head: Follow-up mixed cutting laser head;

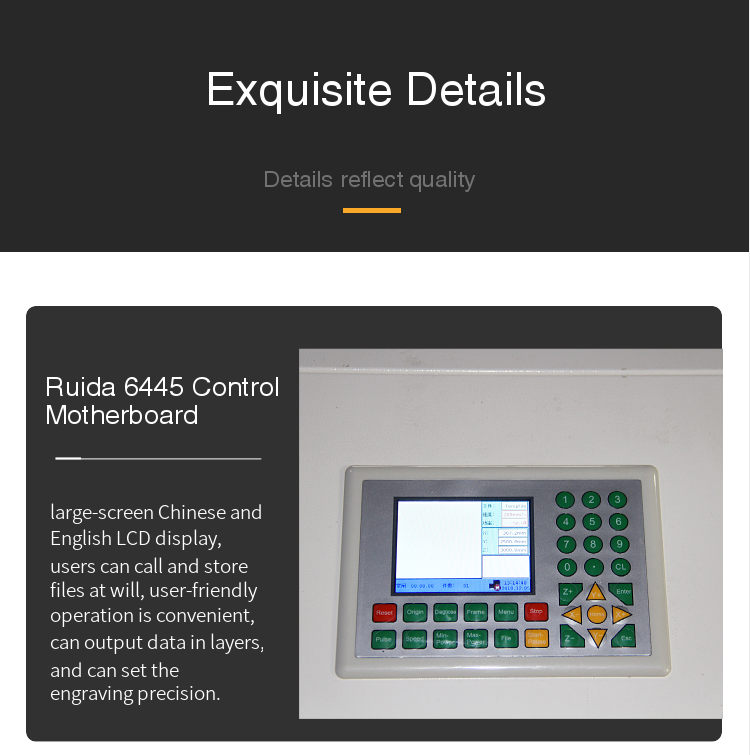

◆ Control System: Ruida 6445 control motherboard;

◆ Working voltage: (220V or 380V) ±10% 50HZ/60HZ.

- Overview

- Related Products

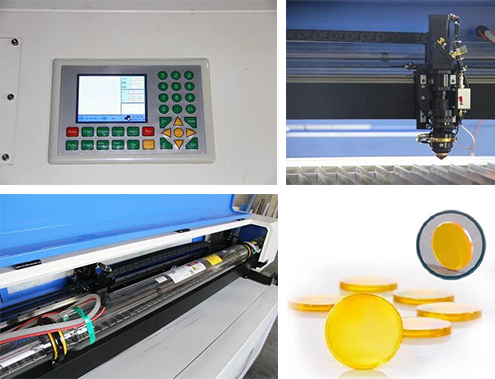

- Graphical Display: The large color screen features a graphical display that supports a preview function, allowing users to visualize the cutting process before execution.

- Power-off Continuous Carving: The motherboard supports power-off continuous carving and slope carving, making operations convenient and efficient.

- Offline Capability: Users can operate the system offline, with data easily transmitted via a USB drive.

- Layered Output: It enables output in layers, allowing users to define parameters separately for each layer for more control over the cutting process.

Product Introduction

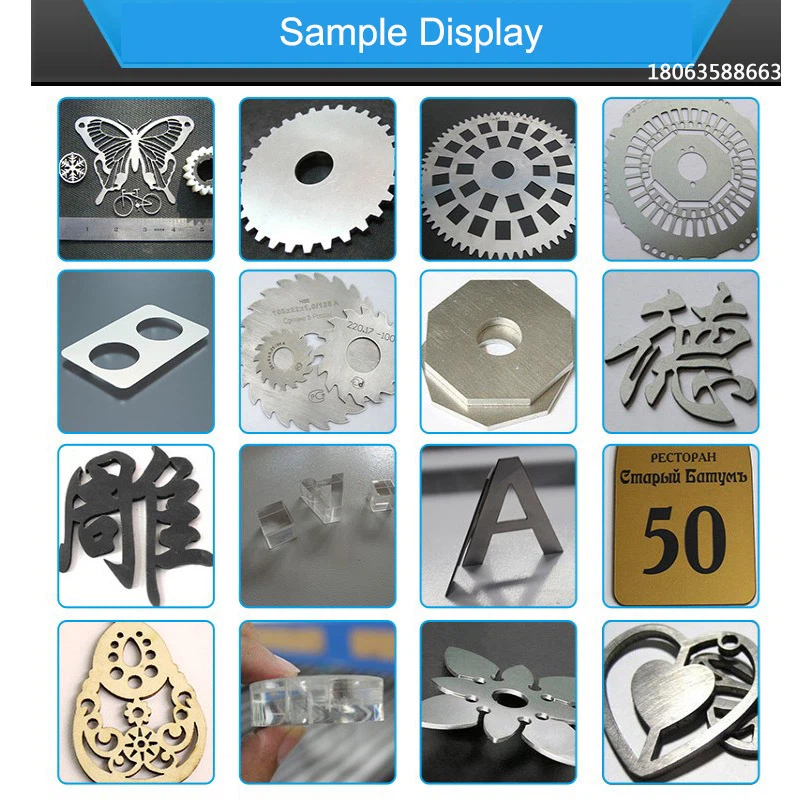

Metal and non-metal laser cutting machines are advanced industrial tools that utilize laser technology to achieve precise cutting of a wide range of materials. These machines can effectively process various metals and non-metals, including low-carbon steel (up to 1.5 mm thick), stainless steel (up to 1.3 mm thick), acrylic (up to 20 mm thick), and medium-density fiberboard (up to 12 mm thick). Additionally, their non-contact cutting method significantly reduces material deformation and waste, achieving material utilization rates of up to 90%.

Product Advantages

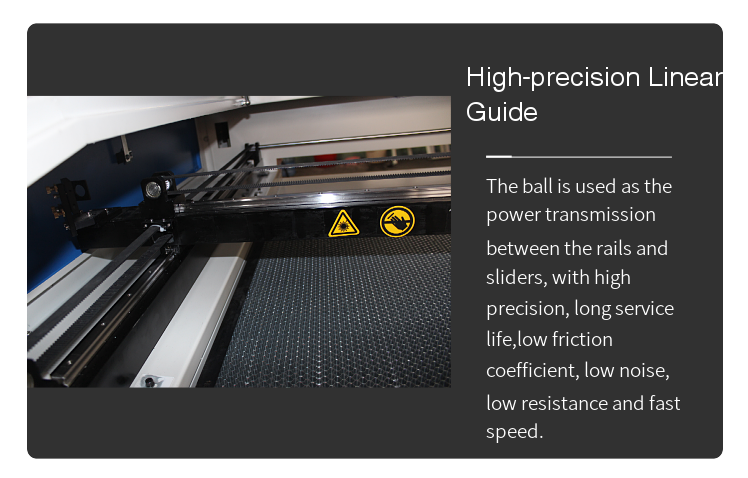

● Enhanced Precision: Metal and non-metal laser cutting machines achieve positioning accuracy of up to 0.01 mm through a series of high-tech components and precision control systems. First, these machines use high-quality optical components and high-resolution laser sources, such as 150W CO2 laser tubes, to ensure that the laser beam is accurately focused and reduce deviations during the cutting process. In addition, the laser cutting machine is equipped with an advanced numerical control (CNC) system, such as the Ruida controller, which can monitor and adjust the laser cutting path in real time to ensure that the cutting head is always accurately aligned with the material.

● Versatility Across Materials: Metal and Non-metal Laser Cutting Machines are capable of processing a wide range of materials, including metals (low carbon steel up to 1.5 mm and stainless steel up to 1.3 mm) and non-metals (such as acrylic and plywood). Through its advanced laser technology and flexible operating parameters. These machines are able to adjust the laser power and cutting speed according to the characteristics of different materials to achieve the best cutting effect.

● vIncreased Production Efficiency: The high-speed cutting capability of laser cutting technology enables the machine to cut mild steel at speeds of up to 18 mm/s, while cutting acrylic with a maximum thickness of 20 mm at 2 mm/s, which greatly shortens production cycles. In addition, advanced CNC systems such as the Ruida controller are able to monitor and adjust the cutting path in real time, ensuring that the cutting head is always accurately aligned with the material, reducing the time required for setup and commissioning.

● Cost-Effective Operation: The use of CO2 laser tubes in these machines ensures a lower power consumption per cut compared to traditional cutting methods. Additionally, reduced material waste due to precise cutting minimizes costs associated with raw materials. For instance, businesses can achieve up to 90% material utilization when using laser cutting, further enhancing cost-effectiveness.

● Minimal Maintenance Requirements: These laser cutting machines are equipped with high-quality water-cooled CO2 laser tubes, which can maintain stable performance during long-term operation. According to industry standards, the service life of these laser tubes can reach 2,000 to 4,000 hours. In addition, the design of the machine contains easy-to-clean structures, such as a detachable tool bed and an integrated air purification system, which reduces the complexity of daily maintenance.

● Improved Safety Features: Metal and Non-metal Laser Cutting Machines come equipped with multiple safety features, including emergency stop buttons, safety interlocks, and ventilation systems to manage fumes. These features help minimize risks for operators and ensure compliance with workplace safety regulations.

Application Materials

Technical Parameters

| Model | HB-H1325 |

| Laser Powder | 150W/180W/300W |

| Processing area | 2500*1300mm |

| Laser head | Follow-up mixed cutting laser head |

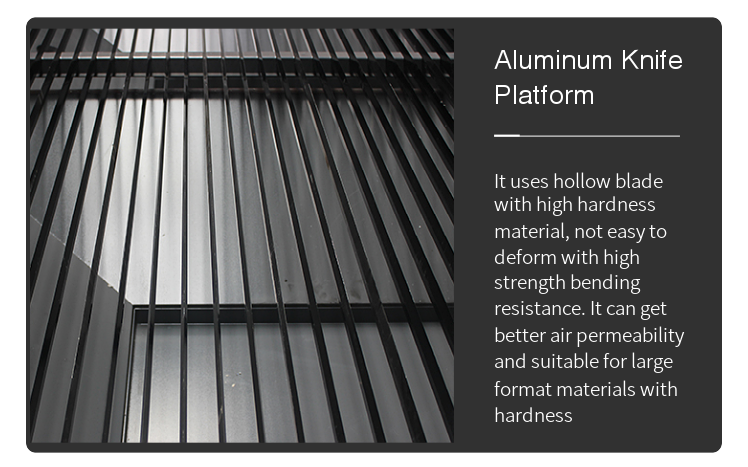

| Working platform | Aluminum knife platform |

| Control System | Ruida 6445 control motherboard |

| Driver | LeiSai Driver |

| Voltage Range | AC220±10% 50HZ/AC380±10% 50HZ |

| Engraving speed | 1200mm/s |

| Cutting speed | 0-500mm/s |

| Cutting depth | 0-20mm(Depending on the material) |

| Minimum Character | 1*1mm |

| Positioning Accuracy | 0.01mm |

| Cooling Method | Water Cooling |

| Supported graphic formats | BMP, PLT, AL, CDR, DXF etc. |

| Item Size | 3210*2010*1130mm |

| Item Weight | 1000kg |

Details

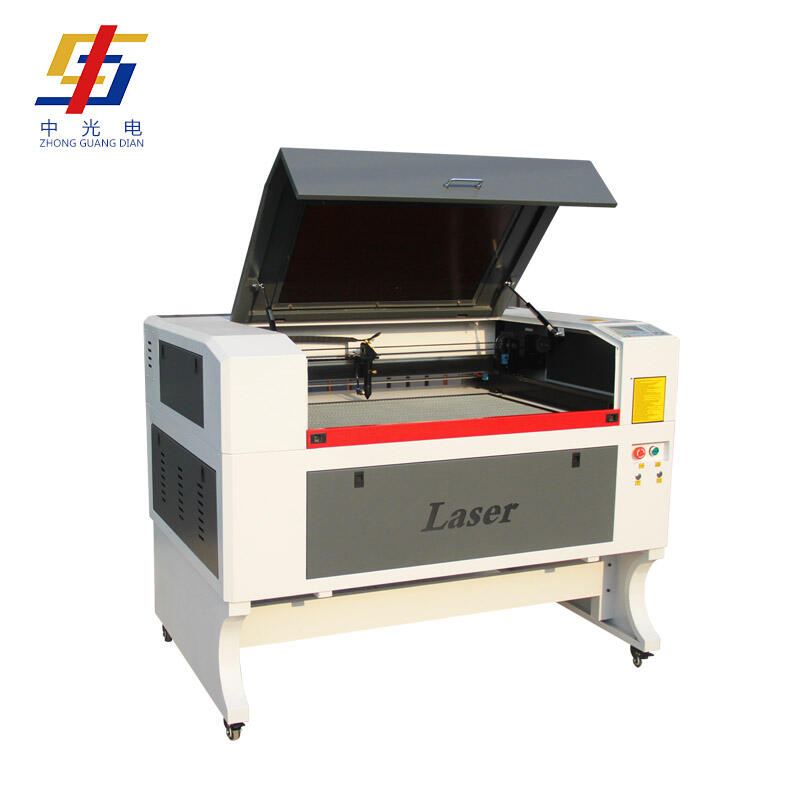

● Mixed Cutting Follow-up Laser Head

The Mixed Cutting Follow-up Laser Head automatically senses the height of the processing material, ensuring precise cutting, even for large formats. Equipped with the advanced Ruida control system, it offers powerful functionalities while remaining user-friendly.

● Large Screen True Color Control Motherboard

● Double-sided Coating Focusing Lens

The double-sided coating focusing lens features a small spot size, ensuring high precision and strong focusing ability. It offers high light transmittance with minimal energy loss, enhancing the overall efficiency of the laser cutting process.

● Famous Brand CO2 Laser Tube

Our high-quality CO2 laser tube is designed for precision and durability. It features a new laser bracket that allows for precise horizontal and vertical adjustments, ensuring flexibility and prolonging the laser's lifespan.

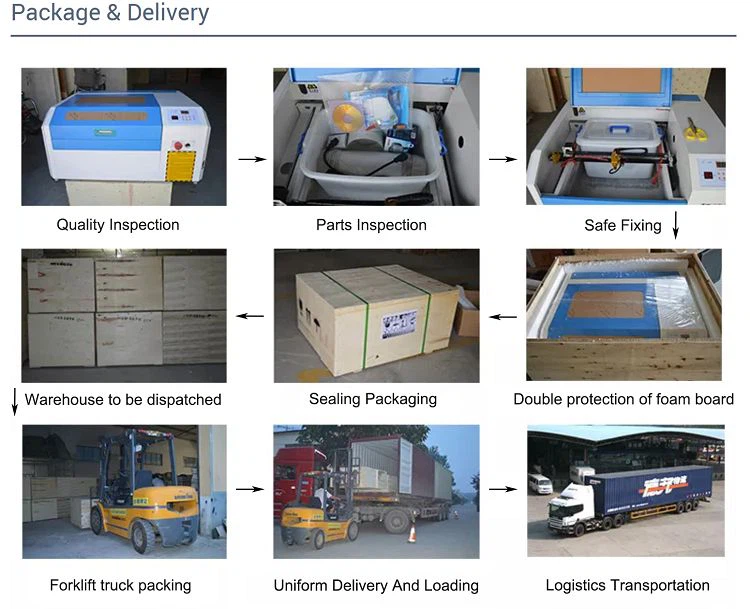

Packaging Process

Factory And Exhibition

Certifications

Hot Tags: metal and non-metal laser cutting machines, China metal and non-metal laser cutting machines manufacturers, suppliers, factory, CO2 Mixed Laser Cutting Machine, Metal And Non metal Laser Cutting Machines, Laser Mixed Cutting Machine, Metal And Non-metal Laser Cutting Machines

Compositions and Package

Main Accessories

FAQ

About the Laser

What materials can I cut or engrave with a CO2 laser?

CO2 laser machine can cut, engrave, mark a wide range of non-metal and organic materials, such as acrylics, woods, plywood, MDF, paper, cardboard, fabrics, leather, glass, stone, ceramics, and more.

What materials can I cut or engrave with a Fiber laser?

Fiber Laser can cut, engrave, mark on metals, such as steel, stainless steel, aluminum, brass, copper, silver, gold, and on some non-metal polymers, wood, fabric.

Shipping

How is the machine packaged?

Laser equipment is shipped in a wooden box with Styrofoam to protect fragile parts

How long does it take to ship by air?

After we receive the order, send the machine to one of the main DHL, FEDEX and TNT offices in China. Smaller machines are shipped by courier service. Typically, it takes 10 to 14 days.

How long does it take to ship by sea?

Larger machines are shipped by sea. Usually, it takes 6 to 10 weeks. We can help you arrange delivery directly to your location.

Customer Support

Is there a warranty?

Manufacturers extend the warranty on their devices to 18 months and replace parts at the factory purchase price.