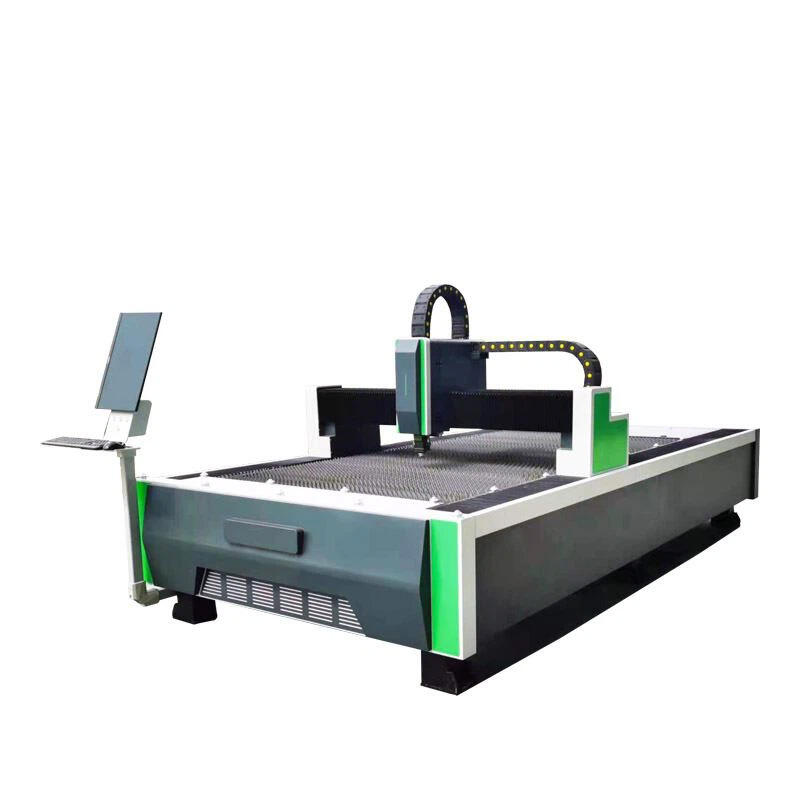

Metal Laser Cutting Machine

◆ 1000w Laser Cutting Machine;

◆ Model: HB-1530;

◆ Laser power: 500W-8000W;

◆ Working area: 1500*3000mm;

- Overview

- Related Products

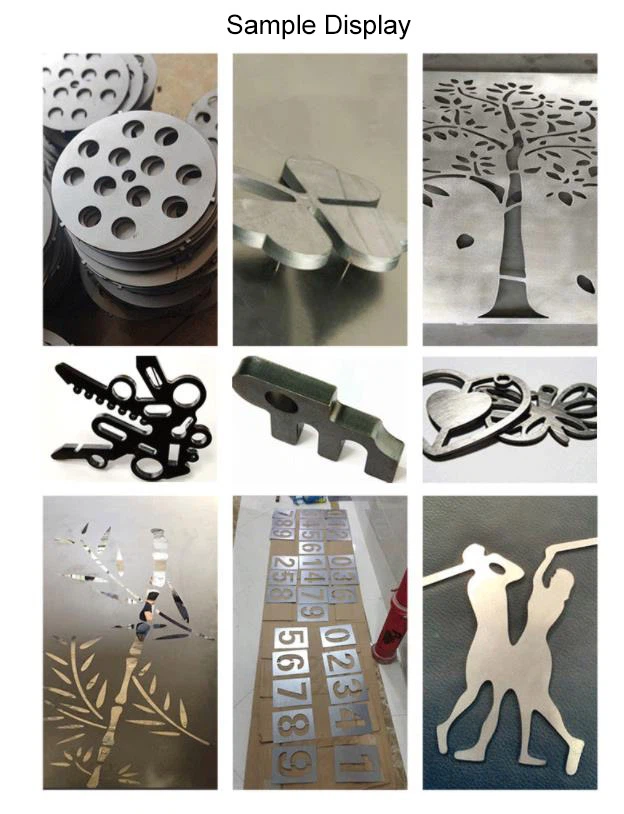

Application Materials

Applied materials:

This fiber laser machine is mainly used for cutting carbon steel, stainless steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials.

Applied Industries:

Fiber laser cutter machine is applied in sheet metal processing, aviation, spaceflight,electronics, electrical appliances, subway parts, automobile, machinery, precisioncomponents, ships, metallurgical equipment, elevator, household appliances, gifts andcrafts, tool processing, adornment, advertising, metal foreign processing variousmanufacturing processing industries,etc.

Our service:

1. Free sample test service: Please send us your CAD(PLT, AI) file, and we will cut the material in our factory and take the video for you. Also, you can send your sample to us first, we will test your sample and show it to you.

2. Customized Machine Design: According to customers' requirements, we can use different brands, such as laser sources, power supplies, laser cutting heads, motherboards, etc., and can design other appearances to meet customer needs.

Technical Parameters

| Model | HB-1530 |

| Brand | HIBO |

| Working Area | 1500mm*3000mm |

| Max Cutting Speed | 60m/min |

| Laser power | 1000w(1500w,2000w,2500w,3000w for option) |

| Max Acceleration | 1G |

| Reset Positioning Accuracy | ±0.01mm |

| Transmission Way | Double racks & pinion |

| Power Requiremennt | 380V/50HZ/3P (220V for option) |

What is the Maximum Cutting Thickness?

| Material | 1000W | 1500W | 2000W | 3000W |

| Carbon Steel (mm) | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-20 |

| Stainless Steel (mm) | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 |

| Aliminum (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-8 |

| Brass (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-6 |

Details

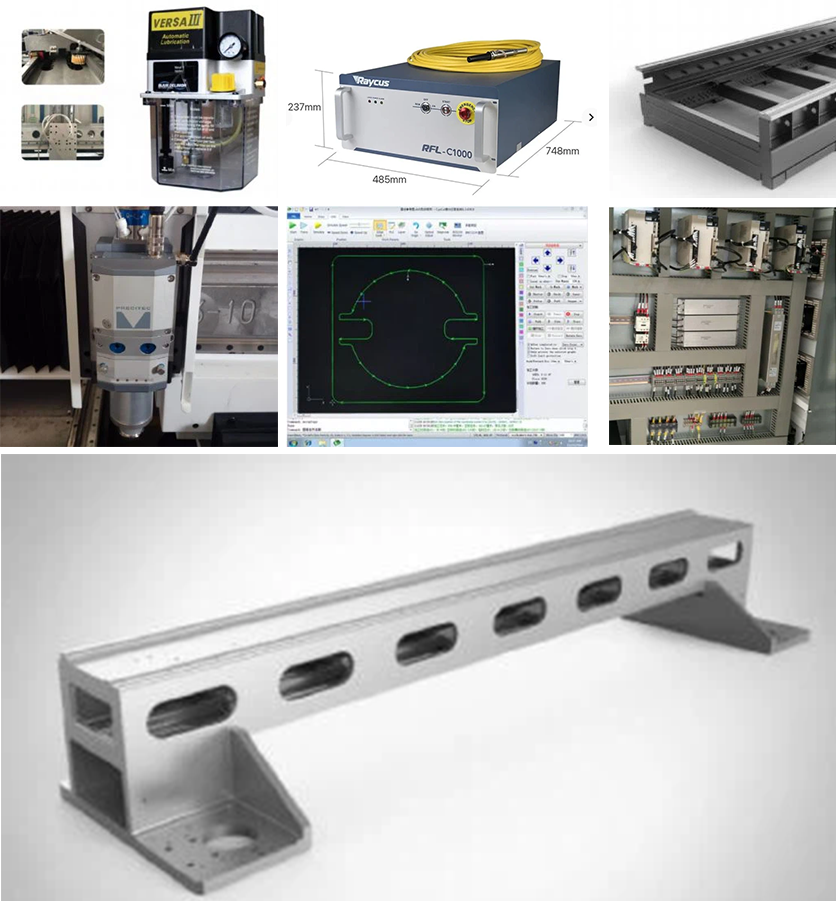

● Raytool Brand Auto sensor laser cutting head.

The Metal Laser Cutting Machine adopts Raytool brand Auto sensor laser cutting head. Raytool is the very famous brand in the world in laser field. it's auto focusing , That can reduce human intervention. It has stable cutting capability under continuous full power.

● Raycus Laser Source

Raycus is largest manufacturer of laser source in China , can cut carbon steel , stainless steel and aluminium etc. Good quality and long life. Suitable for 24 hours continuous working

● Strong Welding Machine Body

High compressive strength and high hardness. Strong shock absorption and wear resistance. Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using, so the machine accuracy could maintain for a long time, and no deformation in a life cycle.

● Cypcut Control System

The operating system can realize intelligent layout of graphics cutting and support the import of multiple graphics, optimizing cutting orders automatically, searching edges smartly and automatic positioning. Control system adopts the best logic programming and software interaction, provides stunning operation experience, effectively enhances the utilization of sheet metal and reducing waste. Simple and fast operation system, efficient and accurate cutting instructions, effectively improve the user experience.

● Japan YASKWA Servo Driver

(1.) Adopting Japan Yaskawa servo motor, adopting closed-loop control method to ensure accurate positioning and dynamic response of the optimum acceleration, which makes the automatic positioning mechanism run smoothly, reliable and maintenance-free.

(2.)X,Y,Z axis high power motor drive, acceleration up to 1.5G.

● Automatic Oil Lubrication System

The automatic oil lubrication system automatically lubricates the guide rail, slider, rack and gear. It can be set by the time and travelled distance. All running parts with oil, prolong their working life, effectively prolongs the life of the machine and reduces wear.

● Cast Aluminum Integrated Beam

The whole structure is made of steel die casting, which is finished after artificial aging and solid solution treatment, so that the beam rigidity, surface quality, integrity, and other performance are all excellent. At the same time, it has the characteristics of high flexibility, which can achieve high-speed cutting of all kinds of graphics under the condition of satisfying precision. All metal laser cutting machines adopt this kind of beam.

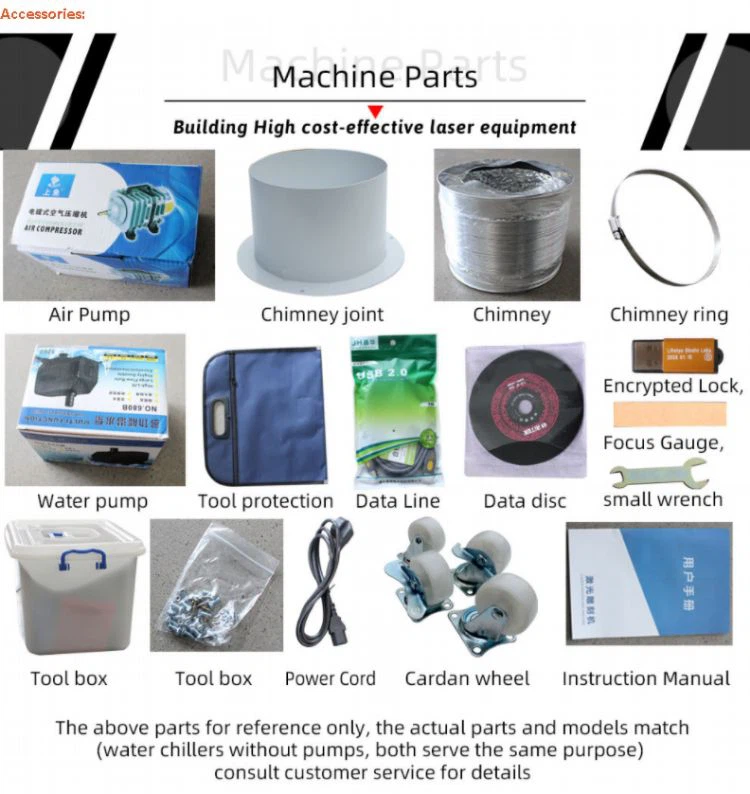

Accessories Shipped with the Machine

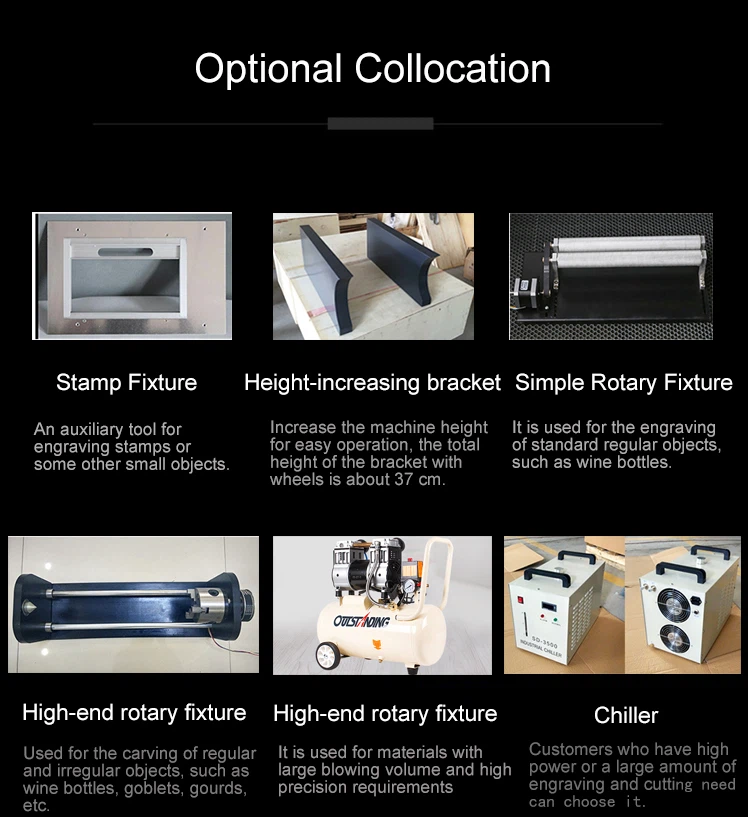

Optional Accessories

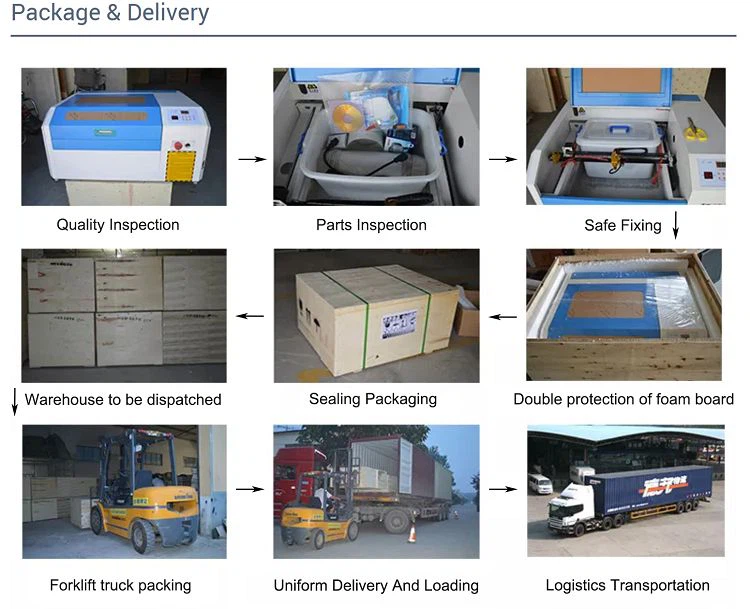

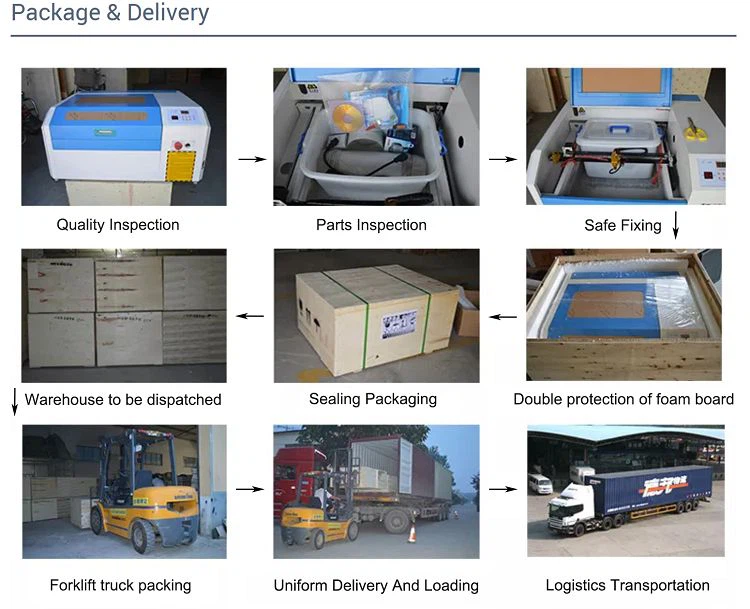

Packaging Process

Factory And Exhibition

Certifications

Hot Tags: metal laser cutting machine, China metal laser cutting machine manufacturers, suppliers, factory, Fiber Laser Cutting Machine, Fiber Laser Metal Cutting Machine

Compositions and Package

Main Accessories

FAQ

About the Laser

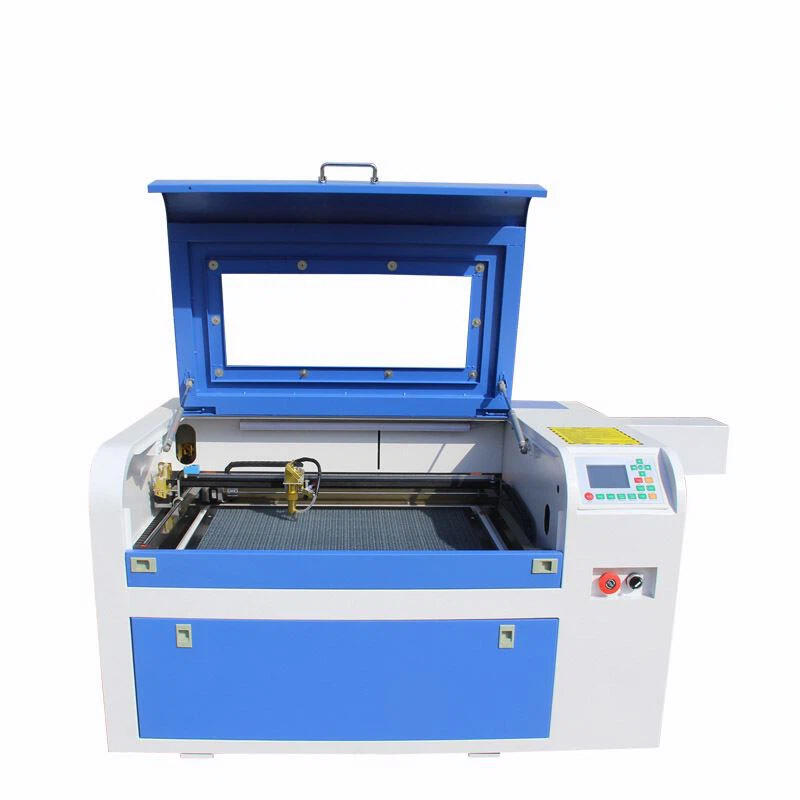

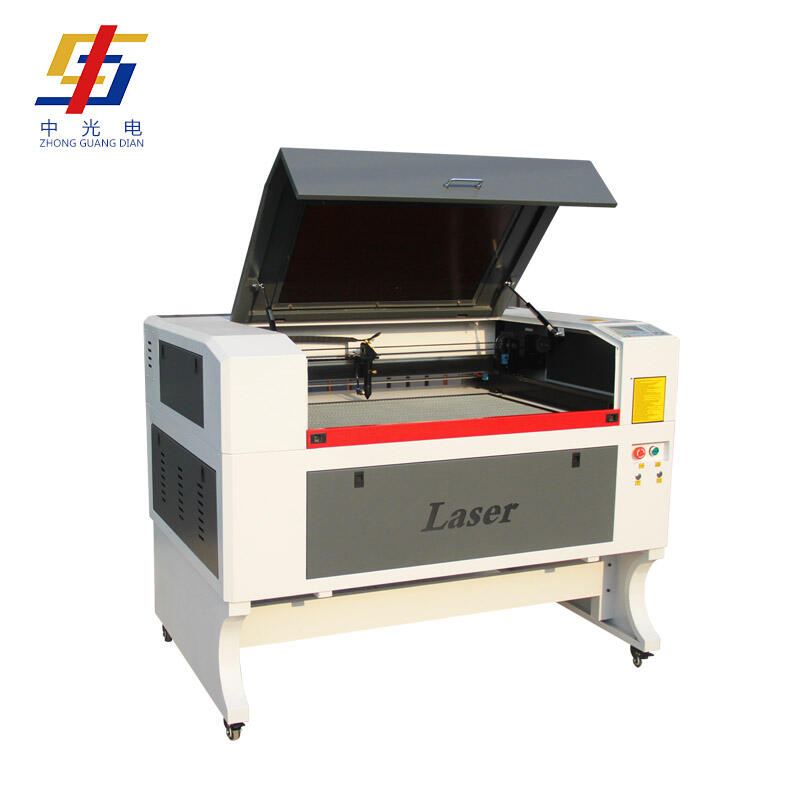

What materials can I cut or engrave with a CO2 laser?

CO2 laser machine can cut, engrave, mark a wide range of non-metal and organic materials, such as acrylics, woods, plywood, MDF, paper, cardboard, fabrics, leather, glass, stone, ceramics, and more.

What materials can I cut or engrave with a Fiber laser?

Fiber Laser can cut, engrave, mark on metals, such as steel, stainless steel, aluminum, brass, copper, silver, gold, and on some non-metal polymers, wood, fabric.

Shipping

How is the machine packaged?

Laser equipment is shipped in a wooden box with Styrofoam to protect fragile parts

How long does it take to ship by air?

After we receive the order, send the machine to one of the main DHL, FEDEX and TNT offices in China. Smaller machines are shipped by courier service. Typically, it takes 10 to 14 days.

How long does it take to ship by sea?

Larger machines are shipped by sea. Usually, it takes 6 to 10 weeks. We can help you arrange delivery directly to your location.

Customer Support

Is there a warranty?

Manufacturers extend the warranty on their devices to 18 months and replace parts at the factory purchase price.